September 1, 2008

Page 15

Quadra-Fire · Topaz · 7009-113G

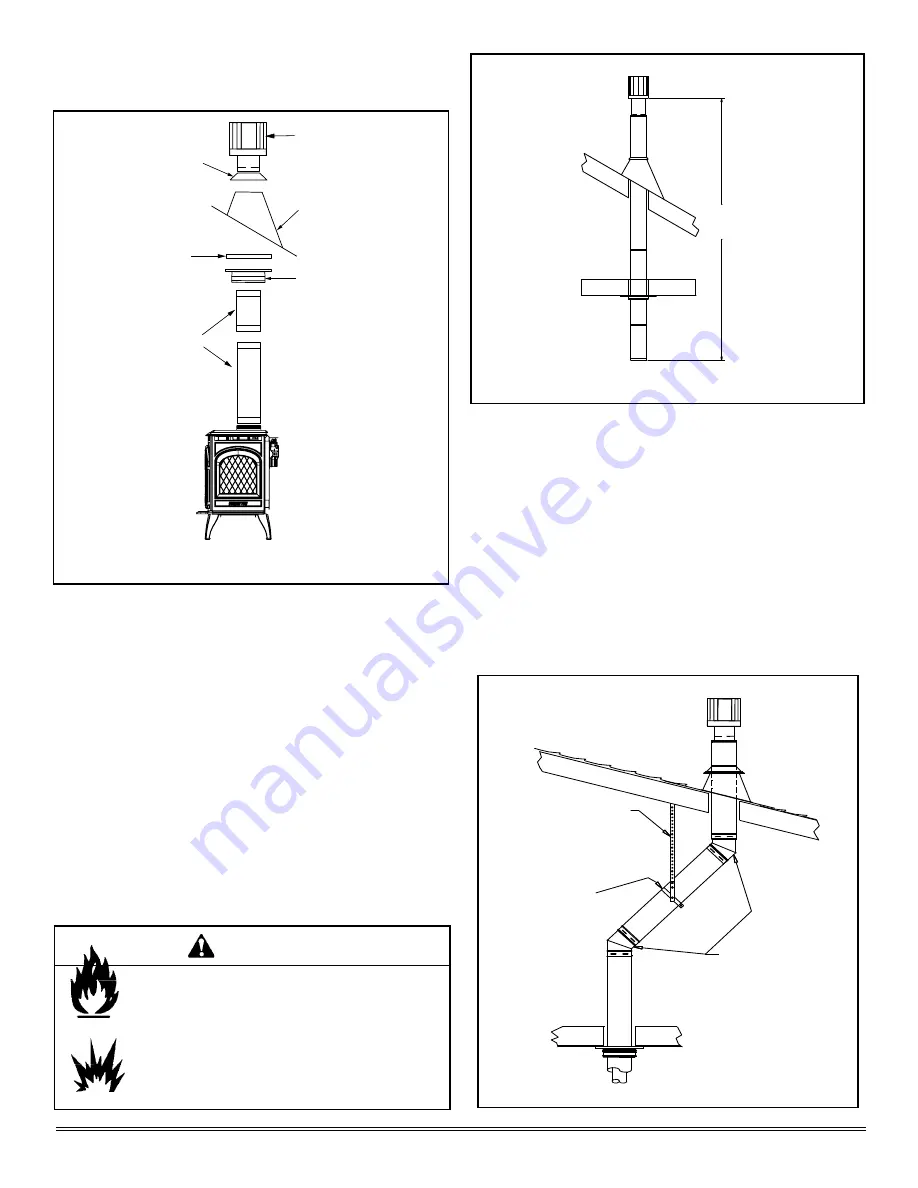

Step 1.

Check the installation instructions for required 1 in. (25mm)

clearances (air space) to combustibles when passing

through ceilings, walls, roofs, enclosures, attic rafters, or

other nearby combustible surfaces. See page 16,

Figure

5.16.

Check the instructions below for maximum vertical rise

of the venting system, and any maximum horizontal offset

limitations. All offsets must fall within the set parameters of

the vent graph (

Figure 5.2

) located on page 11.

NOTE:

Maximum vertical rise allowable is 40 ft. (12m)

Fi

gure 5.11

).

NOTE

: Maximum number of 45° elbows permitted for a

vertical installation is eight, provided their installation

does not decrease maximum allowable horizontal run (as

specified by vent graph, on page 11).

Plumber’s Tape

connected to

Wall Strap

Wall Strap

Two 45˚ Elbows

Step 2.

S

et the gas appliance in its desired location. Drop a plumb

bob down from the ceiling to the position of the appliance

flue exit, and mark the location where the vent will penetrate

the ceiling. Drill a small hole at this point. Next, drop a plumb

bob from the roof to the hole previously drilled in the ceiling,

and mark the spot where the vent will penetrate the roof.

Determine if ceiling joists, roof rafters, or other framing will

obstruct the venting system. You may wish to relocate the

appliance, or to offset, as shown in

Figure 5.12

to avoid

cutting loadbearing members. When location is determined,

drill small hole.

G. Vertical Termination

1. Direct Vent Pipe

Figure 5.10

Figure 5.11

Figure 5.12

Vertical Termination Cap

Storm Collar

Flashing

Firestop

Pipe Length

Support Box

40 ft. (12m)

Maximum

Fire Risk.

Explosion Risk.

Maintain vent clearance to combustibles as speci-

fied.

WARNING

• Do not pack air space with insulation or other

materials.

Failure to keep insulation or other materials away

from vent pipe may cause fire.