6

7080-166B

April 18, 2018

TREKKER

March 19, 2018

QUICK START GUIDE

*Before you plug in this appliance, follow these instructions*

O

pe

ra

tion

Set

U

p

M

an

ual

F

ee

d

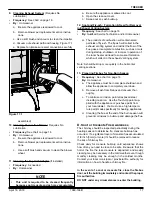

1. Empty

fi re box of

component

packet and

any other

debris.

2. Add pellets

and close

lid.

65

OFF

8:30 AM

MANUAL FEED

ON

65

48

STANDBY

72

65

STANDBY

Set Temperature

8. From the home screen press the outer ring to access the set temperature; rotate

clockwise to raise the temperature and counterclockwise to lower the tempera-

ture.

Note: Refer to the Quadra-Fire Wireless User Interface manual for more infor-

mation.

3. Install user inter-

face per instruc-

tions.

4. Plug in the ap-

pliance

(

exhaust

blower will run for

about 45 seconds,

wait for it to stop

before moving to

manual feed

)

.

65

72

HEATING

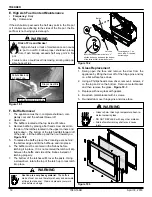

5. From the OFF home screen press and hold the outer ring

for 3 seconds to access the main menu.

6. Rotate to MANUAL FEED from the main menu and press

outer ring to select.

7. Rotate to ON, then press outer ring to start.

• The screen will display FEEDING; either wait for MANUAL FEED to complete

or press OFF to cancel feeding.

• When MANUAL FEED completes the user interface will automatically set

POWER to ON and return to the home screen.

• Refer to Quadra-Fire Wireless User Interface manual for more information.

Note: The MANUAL FEED menu option is only available when your home

screen reads OFF.

Note: MANUAL FEED is required during initial set up of the unit, or after the

unit has alarmed out due to an empty hopper.

C. Quick Start Guide