November 10, 2015

7061-197H

17

Explorer II Medium Wood Stove

Convection

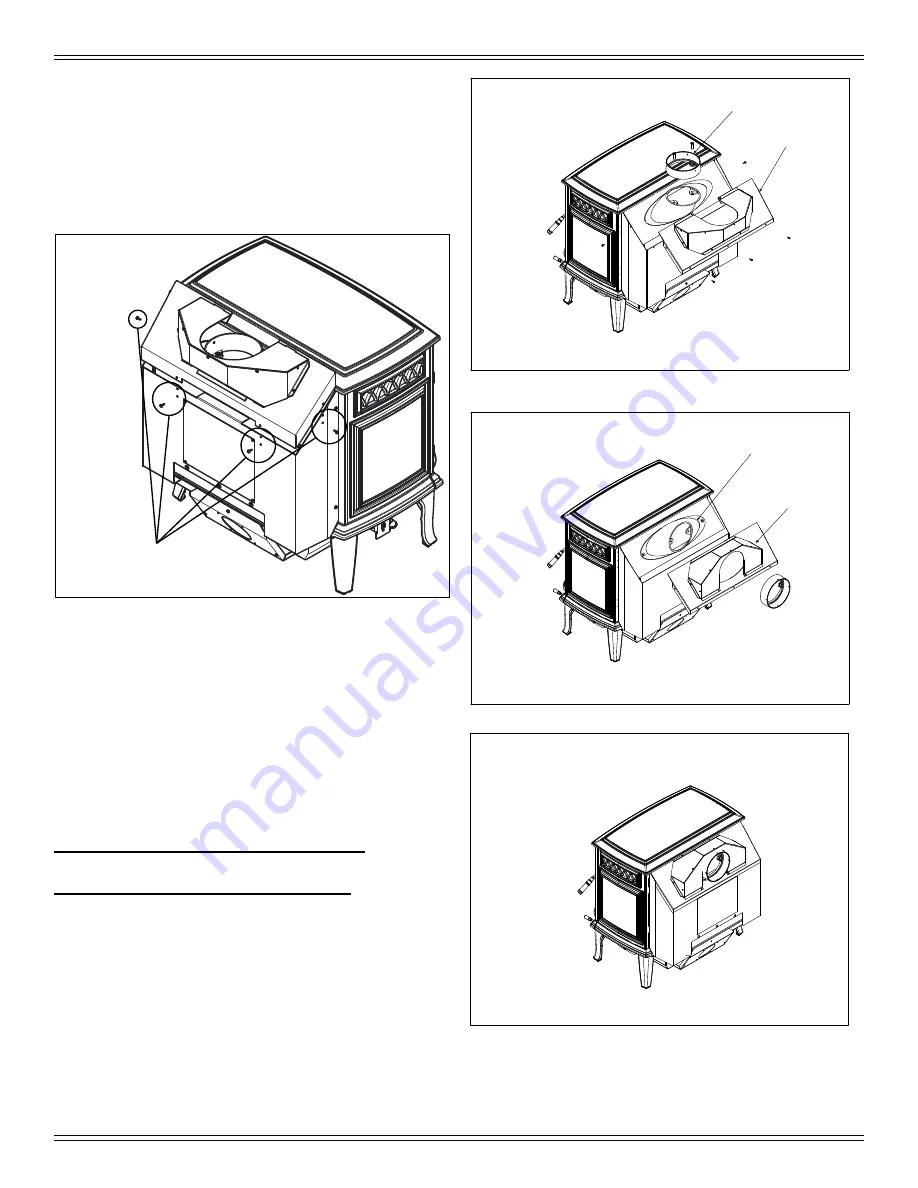

chamber top

Flue collar

Flue transition

Upper flue cover

Figure.17.4.-.Completed.View

Figure.17.2

D...Reversible.Flue.Collar.and.Horizontal.Flue.

Heat Shield

Tools.Required:

#2 & #3 Phillips head screwdriver; 1/2"

wrench

The flue collar is reversible for either a top or rear venting

installation. The appliance is shipped with the flue collar in

the top vent position.

Converting.Collar.Fo

r Rear Vent Installation

and

Installing.Required.Horizontal.Flue.Shield

1. Remove flue collar (#3 Phillips) and convection chamber

top (#2 Phillips).

2. Remove 1 bolt from each side of the flue transition and

retrieve nuts attached to bolts.

3. Turn flue transition to horizontal position. Inspect rope

gasketing to ensure a leak free seal. Re-attach.

4. Remove upper flue cover from convection chamger top.

Rotate 180 degrees and reassebmle. Use paint supplied

to cover unpainted areas.

5. Reattach convection chamber top to flue collar to unit.

Figure.17.3

Mounting Holes

and Screws

C...Blower.(Cont’d)

The convection air top assembly can be raised to redirect

air over the top of the appliance by removing 4 screws and

lifting assembly to align with upper mount holes and reas-

semble.

(Figure.17.1)

NOTE:

This option is not available for horizontal installs.

Figure.17.1