A

Library Addresses

XLS Library Installation Manual

A-5

A.2

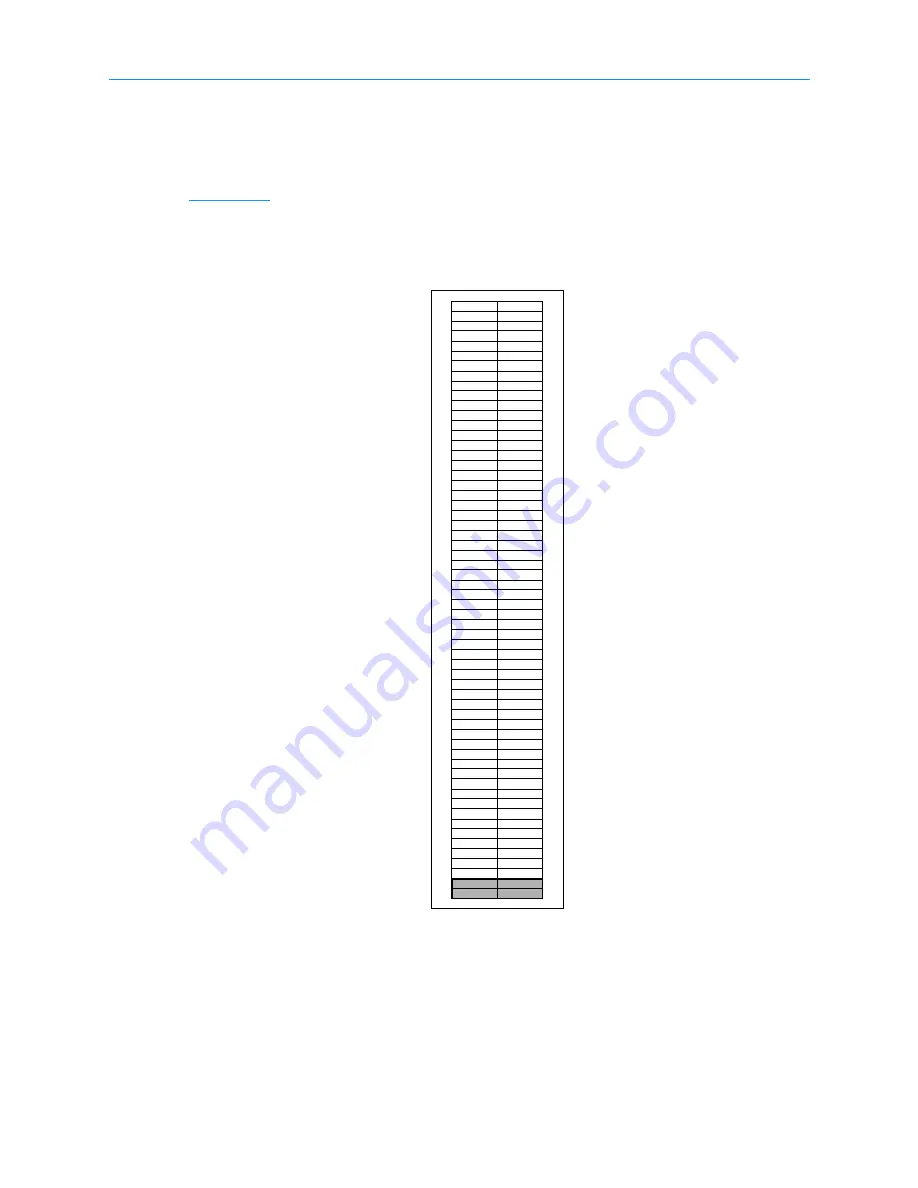

Addresses for Expansion Pod, I/O Ports, and Fixed Port

Slots

shows the physical addresses for the cartridge slots in an XLS-810160/810240

expansion pod.

Figure A-4

Physical addresses for the slots in a XLS-810160/810240 expansion pod

Expansion Pod

A60

A59

A58

A57

A56

A55

A54

A53

A52

A51

A50

A49

A48

A47

A46

A45

A44

A43

A42

A41

A40

A39

A38

A37

A36

A35

A34

A33

A32

A31

A30

A29

A28

A27

A26

A25

A24

A23

A22

A21

A20

A19

A18

A17

A16

A15

A14

A13

A12

A11

A10

A09

A08

A07

A06

A05

A04

A03

B60

B59

B58

B57

B56

B55

B54

B53

B52

B51

B50

B49

B48

B47

B46

B45

B44

B43

B42

B41

B40

B39

B38

B37

B36

B35

B34

B33

B32

B31

B30

B29

B28

B27

B26

B25

B24

B23

B22

B21

B20

B19

B18

B17

B16

B15

B14

B13

B12

B11

B10

B09

B08

B07

B06

B05

B04

B03

Summary of Contents for XLS-810160

Page 1: ...XLS 810160 XLS 810240 Tape Libraries Installation Manual Document No 501801 Rev 07 01 19...

Page 8: ...Table of Contents viii 501801 Rev 07 01 19...

Page 32: ...1 6 For More Information 1 24 501801 Rev 07 01 19...

Page 78: ...6 5 Installing the Rear Side Panel 6 12 501801 Rev 07 01 19 Notes...

Page 100: ...8 2 Connecting the Cables 8 8 501801 Rev 07 01 19 Notes...

Page 114: ...9 3 Logging Into X Link 9 14 501801 Rev 07 01 19 Notes...

Page 154: ...10 6 Defining Other Library Settings and Policies 10 40 501801 Rev 07 01 19 Notes...

Page 168: ...11 3 Viewing the Inventory Report 11 14 501801 Rev 07 01 19 Notes...

Page 182: ...13 3 Scanning the Inventory and Locking the Doors 13 8 501801 Rev 07 01 19 Notes...

Page 198: ...A 3 Addresses for the Media Expansion Module MEM A 8 501801 Rev 07 01 19 Notes...

Page 208: ...Index IN 6 501801 Rev 07 01 19...