4

with each QUANICS product.

To clean the filter:

1. Firmly pull the filter handle and slide the cartridge out of the case.

2. While holding the cartridge over the access opening, rinse off the cartridge with

fresh water, being careful to rinse all septage material back into the tank.

3. Insert the filter cartridge back in the case making sure the cartridge is properly

aligned and completely inserted in the case.

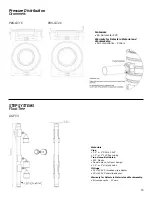

Section 3.0 Dosing Tank

The dosing tank should be inspected for excessive scum and solids build up. There are several commercial

devices that can be used to measure the sludge layer and determine the pumping frequency of the tank.

Homemade devices can also be used to check the sludge level. No matter what you use to check these

levels, the tank should be pumped when the sludge level in the bottom of the tank reaches the bottom of

the filtered pump vault.

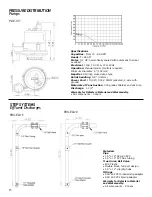

Section 4.0 Filtered Pump Vault

The filter panels on the pump vault should be inspected and cleaned during routine maintenance visits.

However, the filter plates are virtually self-cleaning. The continued action of the anaerobic organisms on

the filter plates causes lodged particle to disintegrate and fall to

the bottom of the tank.

To clean the filter plates:

1. Completely insert the white maintenance plate behind the fil-

ter panel that is to be cleaned.

2. Remove the filter panel. Rinse the filter plates with fresh water

making sure all septage is rinsed back into the tank. The filter

plates should be cleaned until all slots are open and free of de-

bris.

3. Replace the filter panel and remove the white maintenance

plate. Repeat steps 1 and 2 for the second filter panel.

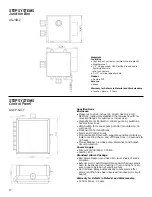

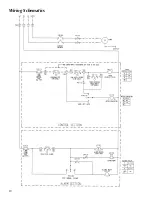

Section 5.0 Controls/Pump/Floats

1. Inspect the floats for proper placement and make certain they are not tangled.

2. Lift the high water alarm float to activate the alarm system to verify proper operation.

3. Open the AC-CP-S-C-T control panel outer door.

4. Activate the pump through the panel manually by moving the HOA switch to Hand.

5. The pump should begin the run and deliver effluent to the treatment module. Trip the floats to test for

proper pump operation

Section 6.0 AeroCell

®

& Bio-COIR

®

Modules

1. A gray biomat on the surfaces of the media may be present and is normal. An excessive accumulation

of solids on the media may indicate that the septic tank is functioning poorly due to excessive household

chemicals or a lack of maintenance. Check with the PROPERTY OWNER about what types of materials

have been discharged. As previously mentioned, excessive bleach, cleaning materials, and other chemi-

cals can upset the septic tank. Advise the owner to restrict the use of such materials.

2. If necessary, rake or stir the upper layer(s) of treatment media. It is normal for the media to settle. It may

be necessary to redistribute the treatment media to allow proper air flow. Coir media is a biodegradable