QUANTECH

48

FORM QWC4-NM1 (221)

ISSUE DATE: 02/28/2021

SECTION 3 - HANDLING, STORAGE, INSTALLATION, AND REASSEMBLY

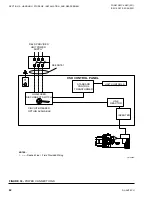

Torque Values

All threaded fasteners shall be torqued to the values

shown in

for the appropriate

bolt materials and gaskets. Values are applicable only

to fiber reinforced, graphite impregnated, teflon, spiral,

jacketed and solid metal gaskets. Cork and low seating

stress gaskets, below 150 psi (1034kPA), are normally

over-bolted and require less torque.

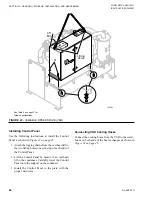

Sealing of the joints, utilizing bulb gaskets, requires

control of the gasket squeeze. For a gasket extend-

ing 3/8 in. above the groove, the squeeze is limited by

maintaining the gap between the surfaces at 3/6 in. +/-

1/16 in. Use the same torque for metal-to-metal contact

outside of the bolt circle. Use the same torque for O-

ring gaskets.

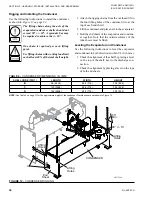

REFRIGERANT TUBING REASSEMBLY

The following is a step-by-step procedure to be used to

reassemble the chiller refrigerant piping.

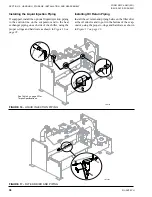

Assembly of Straight Thread O-ring Port

Fittings

The male and female ends of SAE and ISO 6149

straight thread O-ring ports have UN/UNF or metric

straight threads. An elastomeric O-ring is fitted to the

male end. During assembly, the O-ring is firmly sand-

wiched between the angular sealing surface of the fe-

male port and the shoulder of the male end.

Sealing is thus affected and maintained by the O-ring

compression which results from the clamping force

generated by tightening. The straight threads do NOT

offer sealing action; they provide the resistance (hold-

ing power) for service pressure.

Adjustable End Assembly

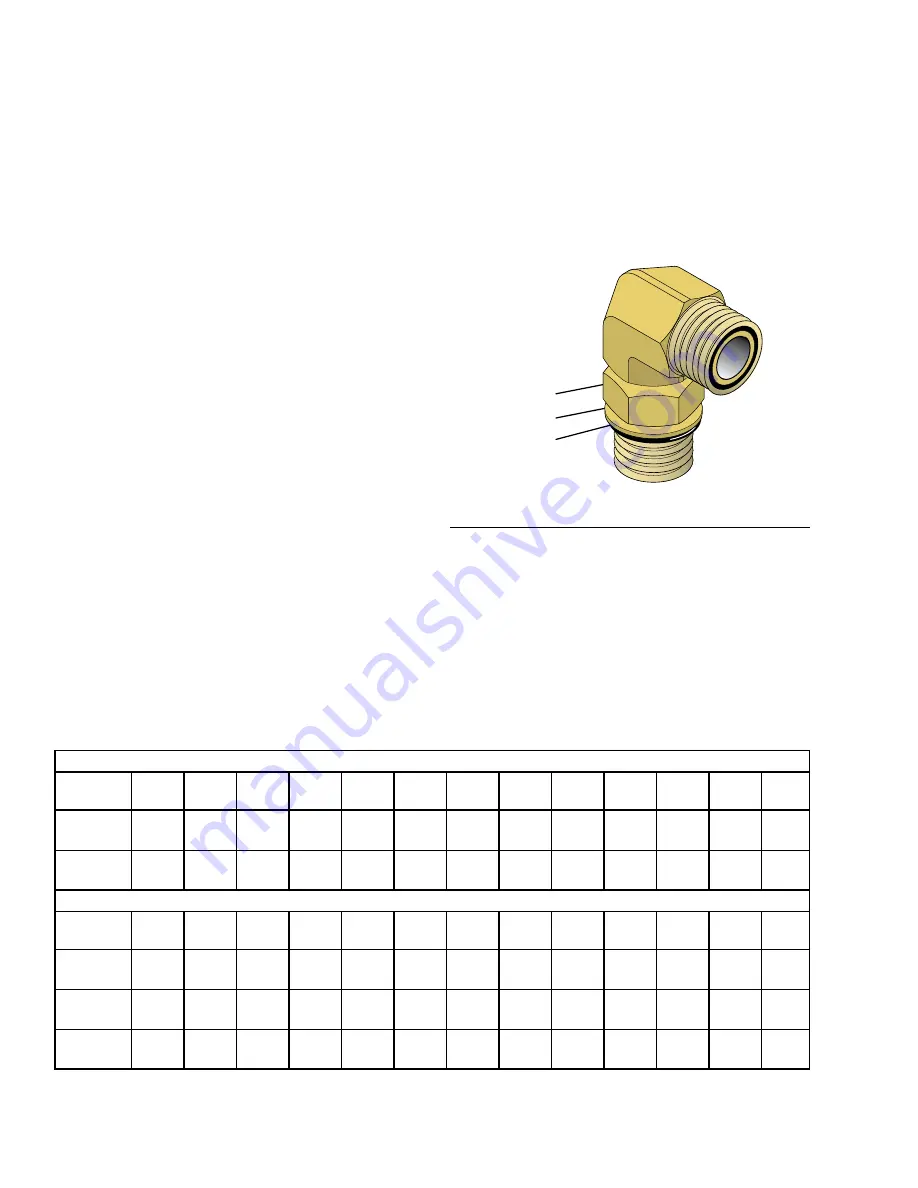

FIGURE 27 -

ADJUSTABLE END FITTING

LD17269

LOCKNUT

O-RING

BACK-UP

WASHER

1. Inspect to ensure that both matching parts are free

of burrs, nicks, scratches or any foreign particles.

2.

Install O-ring on port end of fitting, if it is NOT

pre-installed, take care NOT to nick the O-ring.

3. Lubricate O-ring with a light coat of synthetic

Polyolester (POE) oil or POE grease.

TABLE 13 -

SAE J429 GR 5 BOLTS TORQUE SPECIFICATIONS

HI-STRESS HEAVY DUTY NUTS

BOLT

SIZE (IN)

1/2

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

1 5/8

1 3/4

1 7/8

2

Threads/

in.

13

11

10

9

8

8

8

8

8

8

8

8

8

Thread

Root Area 0.126

0.202

0.302

0.419

0.551

0.728

0.929

1.155

1.405

1.680

1.980

2.304 2.652

LUBRICATION STATUS BOLT TORQUE - TORQUE STATED IN FT-LB

BOLT

SIZE (IN)

1/2

5/8

3/4

7/8

1

1 1/8

1 1/4

1 3/8

1 1/2

1 5/8

1 3/4

1 7/8

2

Threads &

Surface

20–30 40–50 55–65

90–

105

140–

160

190–

210

270–

305

375–

420

500–

555

—

—

—

—

Threads

only

25–35 45–55 65–75

105–

120

165–

185

220–

245

315–

350

430–

470

575–

635

—

—

—

—

Dry - No

lubricant

35–45 60–70

90–

105

145–

165

220–

245

295–

330

420–

465

575–

635

770–

850

—

—

—

—

Summary of Contents for QWC4

Page 14: ...QUANTECH 14 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 64: ...QUANTECH 64 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 82: ...QUANTECH 82 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 130: ...QUANTECH 130 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 146: ...QUANTECH 146 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 152: ...QUANTECH 152 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 155: ...QUANTECH 155 NOTES...