QUANTECH

55

SECTION 3 - HANDLING, STORAGE, INSTALLATION, AND REASSEMBLY

FORM QWC4-NM1 (221)

ISSUE DATE: 02/28/2021

3

FIGURE 34 -

LEAVING WATER TEMPERATURE

OUT-OF-RANGE SUGGESTED

LAYOUT

LD17279

Supply

to

Load

Return

from

Load

Recirculation

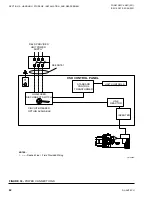

VARIABLE PRIMARY FLOW

Use a maximum 10% per minute flow rate of change,

based on design flow, for variable primary flow appli-

cations. Provide 8 gal to 10 gal per chiller ton (8.6 L to

10.8 L per cooling KW) system water volume. Insuffi-

cient system volume and rapid flow changes can cause

control problems or chiller shutdowns. There are many

other design issues to evaluate with variable primary

flow systems. Consult the Quantech Sales Office for

more information about successfully applying QWC4

chillers.

NOZZLE CONNECTIONS

Standard chilled liquid connections on all coolers and

condensers are the grooved type as shown in the fol-

lowing figure

.

FIGURE 35 -

GROOVED NOZZLE

LD10494

OPTIONS FOR FLANGES

Two types of flanges may be fitted, depending on the

customer or local pressure vessel code requirements as

. Weld flanges are

supplied loose or ready-fitted; grooved adapters are

supplied loose.

The flange dimensions are to ISO 7005 - NP10.

LD29433

WELD FLANGE

GROOVED ADAPTER

FIGURE 36 -

FLANGE ATTACHMENT

REFRIGERANT RELIEF PIPING

In case of an emergency, each unit is equipped with a

relief valve on the evaporator, condenser and oil sepa-

rator discharge line to quickly relieve excess pressure

of the refrigerant charge to the atmosphere. The relief

valves are furnished in accordance with the American

Society of Heating, Refrigeration and Air Conditioning

Engineers Standard 15 (ASHRAE 15) in North Amer-

ica, or PED code in Europe. Valve specifications are

.

Refrigerant relief vent piping (by others), from the re-

lief valves to the outside of the building, is required

by code, and must be installed on all units as shown in

For additional information on

relief valve discharge line sizing, refer to ASHRAE 15

Addendum 15C and 15D-2000, Section 9.7.8.5.

If relief piping is common to more than one valve, its

cross-sectional area must be at least the total required

by each valve. Valve types should not be mixed on a

common pipe. Take precautions to make sure that the

outlets of relief valves or relief valve vent pipes remain

clear of obstructions at all times.

Piping must be properly supported to pre-

vent any strain on relief valve mounting.

Summary of Contents for QWC4

Page 14: ...QUANTECH 14 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 64: ...QUANTECH 64 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 82: ...QUANTECH 82 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 130: ...QUANTECH 130 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 146: ...QUANTECH 146 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 152: ...QUANTECH 152 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 155: ...QUANTECH 155 NOTES...