QUANTECH

77

FORM QWC4-NM1 (221)

ISSUE DATE: 02/28/2021

5

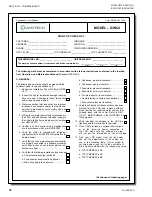

SECTION 5 - COMMISSIONING

PREPARATION

Commissioning of this unit should only

be carried out by Quantech authorized

personnel. Proper electrical lock out/tag

out procedures must be followed.

Make sure all checks are completed in the

Start-up

Checklist (Form QWC4-CL3)

on the next page. The

chiller is then ready to be placed into operation.

Commissioning personnel should be thoroughly fa-

miliar with the information contained in this document

before starting the unit.

For helpful tips about commissioning the unit, see the

following information.

Refrigerant Charge

Packaged units are normally shipped as standard with

a full refrigerant operating charge. See the following

instructions to make sure the refrigerant is handled

correctly.

• Do not evacuate or liquid charge with static water

in the cooler or condenser.

• Turn on the pumps.

• Vapor charge until the system pressure is above

the saturated temperature for freezing of the fluid

in the evaporator and condenser.

• Liquid charge slowly to avoid excessive thermal

stress at the charging point, and to make sure the

refrigerant temperature does not go below the

freezing point with liquid refrigerant in the evap-

orator and condenser.

• Evacuation and charging should always be done

according to

.

Service and Oil Line Valves

If valves are of the back-seat type, open them fully

(counterclockwise), then close one turn of the stem.

Compressor Oil

While the compressor is running at design speed, the

oil level should be visible between the bottom of the

lower and middle of the upper sight glass of the oil

separator.

Make sure that the compressor heaters

have been energized at least 24 hours

before starting the chiller.

FIRST TIME START-UP

During the commissioning period, there

should be sufficient heat load to run the

unit under stable full load operation to

enable the unit controls, and system op-

eration to be set up correctly, and a com-

missioning log taken.

When a compressor is running, the controller monitors

oil pressure, motor current, and various other system

parameters, such as discharge pressure, chilled liquid

temperature, etc. Should any problems occur; the con-

trol system will immediately take appropriate action

and display the nature of the fault.

Loading

Once the unit has been started, all operations are fully

automatic. After an initial period at minimum capacity,

the control system will adjust the unit load depending

on the chilled liquid temperature and rate of tempera-

ture change. If a high heat load is present, the control-

ler will increase the speed of the compressor.

Summary of Contents for QWC4

Page 14: ...QUANTECH 14 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 64: ...QUANTECH 64 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 82: ...QUANTECH 82 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 130: ...QUANTECH 130 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 146: ...QUANTECH 146 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 152: ...QUANTECH 152 FORM QWC4 NM1 221 ISSUE DATE 02 28 2021 THIS PAGE IS INTENTIONALLY LEFT BLANK...

Page 155: ...QUANTECH 155 NOTES...