2.0 Set basic Function

The WTG

Q

uantor

multifunction controller has three functions:

APP 1 Ice bench controller

APP 2 Temperature controller for wet cooler

APP 3 Temperature controller for dry cooler

The selected function is set when booting the controller:

Press and hold, at the same time connect the power supply to the controller or the chiller.

After the functional test of all displays, the display will show APP 1, 2, 3.

let go

or

Press to select the corresponding function.

The input is confirmed by the controller with "Y".

Please note! The functions can only be put into operation if the corresponding sensors are

installed.

3.0 Programming Menu.

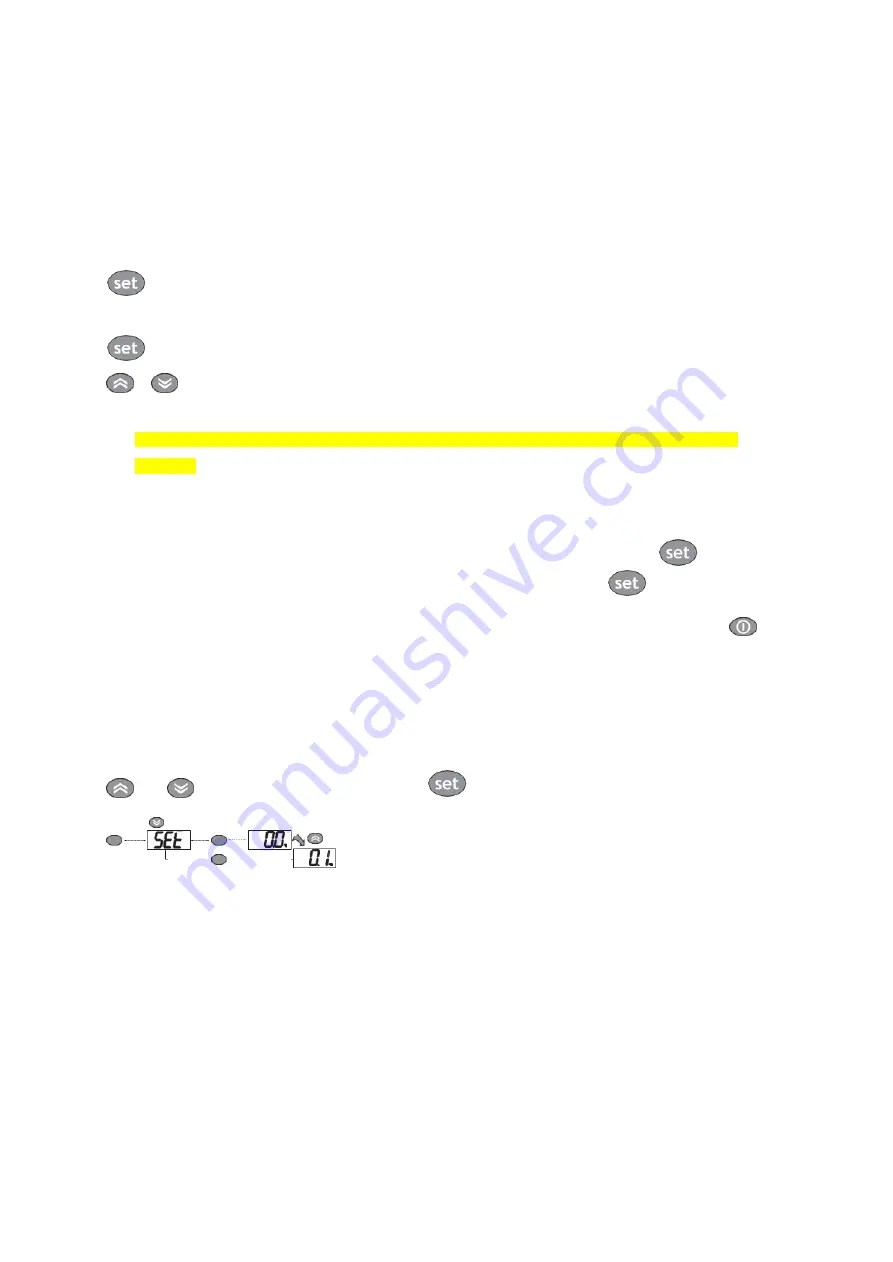

The resources organized in menus can be accessed by pressing and releasing the

(menu "Basic commands") or by pressing the key for more than 5 seconds.

("Programming" menu) can be accessed.

If the keyboard is not used for more than 15 seconds (timeout) or after pressing the key once

the last value shown on the display is taken over and the previous display is shown again.

4.0 Set Point Adjustment

To display the set point, press "SET" when the label is displayed.

The setpoint appears on the display. To change the setpoint within 15 seconds, press the keys

and

press. The change by pressing

take over.

6. Cleaning of the cooling unit

Casing: Before cleaning the units disconnect the mains plug! Please do not use water

directly on the unit, clean only with a wet cloth and a little dish liquid. The cleaning of

the units and the beverage coils have to take place according to the instructions of the

industrial safety regulations.

Prevent any moisture from getting into the electric part of the unit!

The condenser shouldbe cleaned at regular intervals (min. every sixmonths) by qualified

personnel to remove the accumulated air dust.

Summary of Contents for ICECHILLY

Page 11: ......