Owner’s Manual

Quantum Energy Technologies

Document number: QDC0030PD-16.4 Page 28 of 36

Appendix A: TROUBLE SHOOTING GUIDE ON QUANTUM WATER

Models covered in this guide

:

800 Watt. Compact and Split Air Source Domestic Hot Water Heater (0.8kW compressor models):

150/200-08ACW-134; 150/200-08ASW-134

1100 Watt. Compact and Split Air Source Domestic Hot Water Heaters (1.1kW compressor models):

270/340-11AC3-134; 270/340-11AC4-134; 270/340-11AS4-134

1700 Watt

.

Titan and Split Compact & Split Air Source Hot Water Heaters (1.7kW compressor models):

340-17ACW-134; 340-17ASW-134

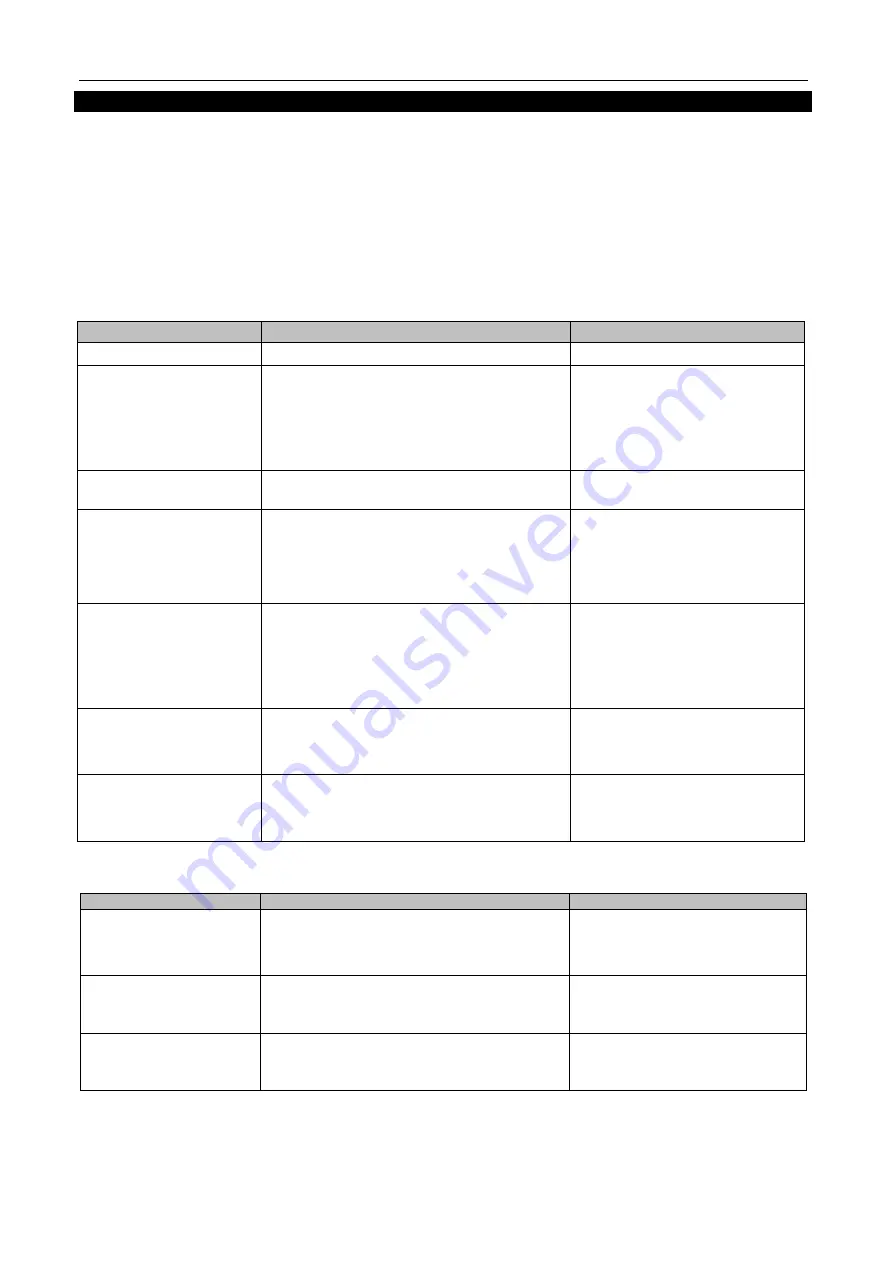

A.1: No Hot Water; Compressor Not Running

Probable Cause

Test / Observation

Action

1. Power Failure

Check power supply, cable & connections.

If CB off refer to 2.

2. Circuit breaker (CB)

tripped off.

Check for short circuit (SC) in line or

wiring.

If circuit breaker trips off when compressor

re-starts, check compressor grounding and

winding resistance.

Remove line or wiring SC.

Replace compressor if found

SC.

3. Faulty / incorrect

capacitor.

Check capacitor operation if compressor

will not start.

Replace faulty or wrong

capacitor.

4. Compressor Seized.

Compressor will not start, draws high

current, or mechanically noisy when trying

to start.

Check the voltage.

Hit the compressor gently by a

wood hammer.

Replace compressor.

5. Thermal cut-out (TCO)

on digital controller

tripped off.

No power to compressor after thermal cut

out (TCO).

If TCO trips off repeatedly, see table “A2”.

Reset the TCO by pressing the

“

SET

” button on the digital

controller.

Check the gas amount from

sight glass.

6. Faulty water

thermostat.

Thermostat did not cut in even though

water temperature is below the restart point.

Electrical disconnection at the thermostat.

Check / replace water thermostat

or digital controller.

Reconnect or replace if faulty.

7. Compressor cuts out

on current overload

protector

Test for faulty capacitor.

Test for compressor short circuit /

compressor seized

Replace faulty capacitor

Replace compressor if faulty

A.2: Thermal Cut Out Trips Off Repeatedly

Probable Cause

Test / Observation

Action

1. Low refrigerant

charge.

Check refrigerant charge.

Test for possible leak in the refrigeration

circuit.

Top up refrigerant or re-charge.

Repair leak, or if not repairable,

contact QUANTUM service.

2. High refrigerant

charge.

Check refrigerant charge. Over charge

causes high current draw and excessive

head pressure resulting in a hot compressor.

Correct the refrigerant charge.

3. Incorrect voltage and

frequency.

Check power supply quality while unit is

running.

Rectify improper power supply

or shut off system and report to

the client.