Owners Manual

Quantum Energy Technologies

Section 5: OPERATION

5a: Pre Start Up

1.

The hot-water system should be flushed and cleaned. Proper water treatment is required to

prevent corrosion and scale formation on the condenser.

2.

Inspect all water piping for flow direction and correct connections at the condenser.

3.

Open all electric disconnects and check all electric connections for tightness. Check unit power

supply wiring for proper amperage and a minimum insulation temperature of 75°C. Check for

proper phasing using a phase sequence meter.

4.

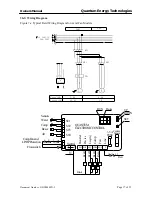

Verify water temperature sensor is installed in the exiting water line (supply to a water tank or

building) for water heaters and building heaters, and the entering water line for pool heaters. On

all Quantum units the sensors are factory mounted.

5.

Check that the voltage of the power supply to the unit is within ±10% of the nameplate rating.

Verify all mechanical and electrical inspections have been completed according to local codes.

6.

Turn on the controller via the on/off switch mounted on the left panel of the cabinet. The

Digital Controller will display the current water outlet temperature (for building heaters and

water heaters) and the inlet temperature (for pool heaters). This will energize the system. (If

crankcase heater is equipped, wait at least

24 hours

before starting up the unit.)

7.

Open all water flow valves and start the hot water pump. Check all piping for leaks and vent the

air from the condenser as well as from the system plumbing for a building heater.

5b: Commissioning

1.

If the controller calls for heating, the unit will begin the start-up sequence. Please be aware that

there is a 10-minute time delay, after activation, prior to a compressor start.

2.

After running the unit for a short time, check the rotation of fans, and flashing in refrigerant

sight glass. The refrigerant sight glass should be clear with a solid column of liquid visible.

3.

Allow the compressor to run a short time, but at the same time be ready to stop it immediately if

any unusual noise or adverse conditions appear.

4.

With an ammeter, verify that each phase of the compressor and the fan(s) are within the RLA as

listed under Electrical Data.

Adjust the damper for the centrifugal fan system to ensure that the

electrical current for each fan is less than 4 amps

.

5.

Check the system operating parameters such as the head pressure and the water temperature as

well as the suction pressure and the ambient temperature. The pressures can be measured with

manifold gauges.

6.

Verify superheat temperature is in the range of 4°C – 7°C at about 10°C ambient. The superheat

may be large, at low ambient temperatures for a TX valve, and at high ambient temperature for

an Electronic Expansion Valve. The superheat for an Electronic Expansion Valve is determined

from the suction temperature and the suction pressure measured by the gauge, not directly read

from the controller.

Document Number : QDC0049PD-5

Page 22 of 33