5

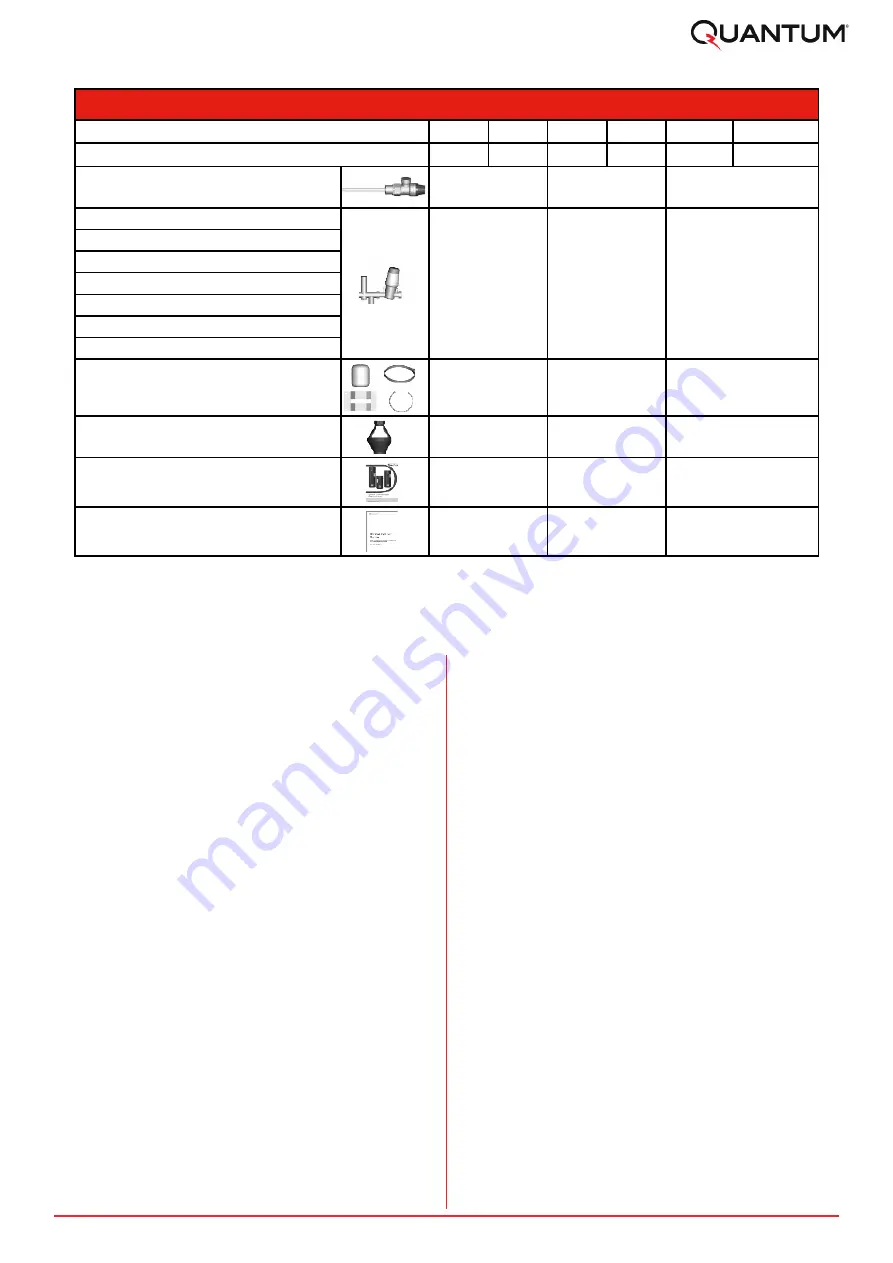

Scope of Delivery

125l

150l

180l

210l

250l

300l

2

2

2

2

2

2

- connection for expansion vessel

- balanced cold water supply port

Scope of delivery

T+P valve *

Cylinder volume

Cylinder with 3kW immersion *

1/2”, 7bar/90°C

1/2”, 7bar/90°C

Terms and conditions x 1

Inlet control group consisting of:-

Expansion vessel with fixing kit and

connection hose

Tundish

Installation & User Instructions x 1

- in line strainer

- 3 bar PRV

- 6 bar ERV

- non-return valve

15mm/22mm

12 l

24 l

15mm/22mm

1/2”, 7bar/90°C

18 l

15mm/22mm

4

Scope of Delivery

Table 1: Scope of Delivery for Quantum Cylinders

5 Pre-Installation

Please read the following section carefully before

commencing installation. If in any doubt, please

call the appropriate help desk. Disregarding the

instructions given in this manual in its entirety

and any relevant regulations, standards and codes

of practice will void the guarantee of this product.

Handling

– depending on the size of the unit and

access to its installation location,

consideration must be given to the handling of the

unit. Please note that handling, installation and

use of this product is subject to the Health and

Safety at Work Act. If the unit is not installed im-

mediately, it should remain in its protective pack-

aging with all pipe protectors/end caps

applied to prevent damage and dirt deposit inside

the cylinder.

Pipework

– the pipe runs should be executed

as short as possible, unused pipework should be

removed and all remaining pipework should be

lagged in accordance with regulatory

requirements to prevent heat loss and the

formation of condensation.

Taps and Fittings

– all taps and fittings incorpo

-

rated in the unvented system should have a rated

operating pressure of 0.6 MPa (6 bar) or above.

5.1 Risk Assessment

The compilation of a risk assessment is strongly

recommended before installing the product. The

following areas require particular consideration in

addition to the information required by the Health

and Safety at Work Act.

Scalding

- where appropriate or required by law

a thermostatic mixing valve is to be fitted to the

hot water outlet of the cylinder (see also water

borne organisms).

Explosion

- the unit is fully equipped with all

relevant safety equipment to comply with current

regulations. The correct design and function has

been verified by independent third party testing.

The correct application thereof is the responsibility

of the installer.

Water Borne Organisms (i.e. Legionella)

-

if applicable a risk assessment should be carried

out following the recommendations outlined in the

Approved Code of Practice L8.

The user preference must be considered when

commissioning the system, in particular when

adjusting the temperature and timer settings.

*These items are supplied factory fitted

Summary of Contents for IOT Series

Page 12: ...12 Installation Figure 9 Wiring Schematic...

Page 31: ...31 Notes...

Page 32: ...32 Notes...

Page 33: ...33 Notes...