90 Chapter 10 In-service field maintenance for 2U enclosures

10 In-service field maintenance for 2U enclosures

You may service the identified storage enclosure FRUs and still maintain continuous operation during the

replacement, but with two very important qualifiers:

l

You must determine whether your system allows for continuous operation during service replacement of

the storage enclosure drive modules in their carriers (DDICs) without interrupting access to enclosure file

systems.

l

You must complete the replacement in the allotted time, replacing only one FRU at a time. The storage

enclosure design provides for redundancy, so the loss of a single FRU does not impact functionality for a

limited time.

The tasks identified in this chapter first cover FRUs in the drawers, followed by FRUs accessible from the rear

panel area. It is essential you adhere to all safety precautions when servicing storage enclosure FRUs.

CAUTION When performing maintenance on the storage enclosure or its components:

l

Observe the caution label affixed to each drive module or FRU prior to handling or replacing it.

l

Do not remove a defective FRU until you have its functional replacement ready for insertion.

To adhere to safety precautions when replacing a FRU in a storage enclosure:

1. Replace any defective FRU with a fully operational one as soon as possible.

2. Replace any defective FRU within the identified replacement time to minimize air loss and maintain

optimum cooling within the storage enclosure.

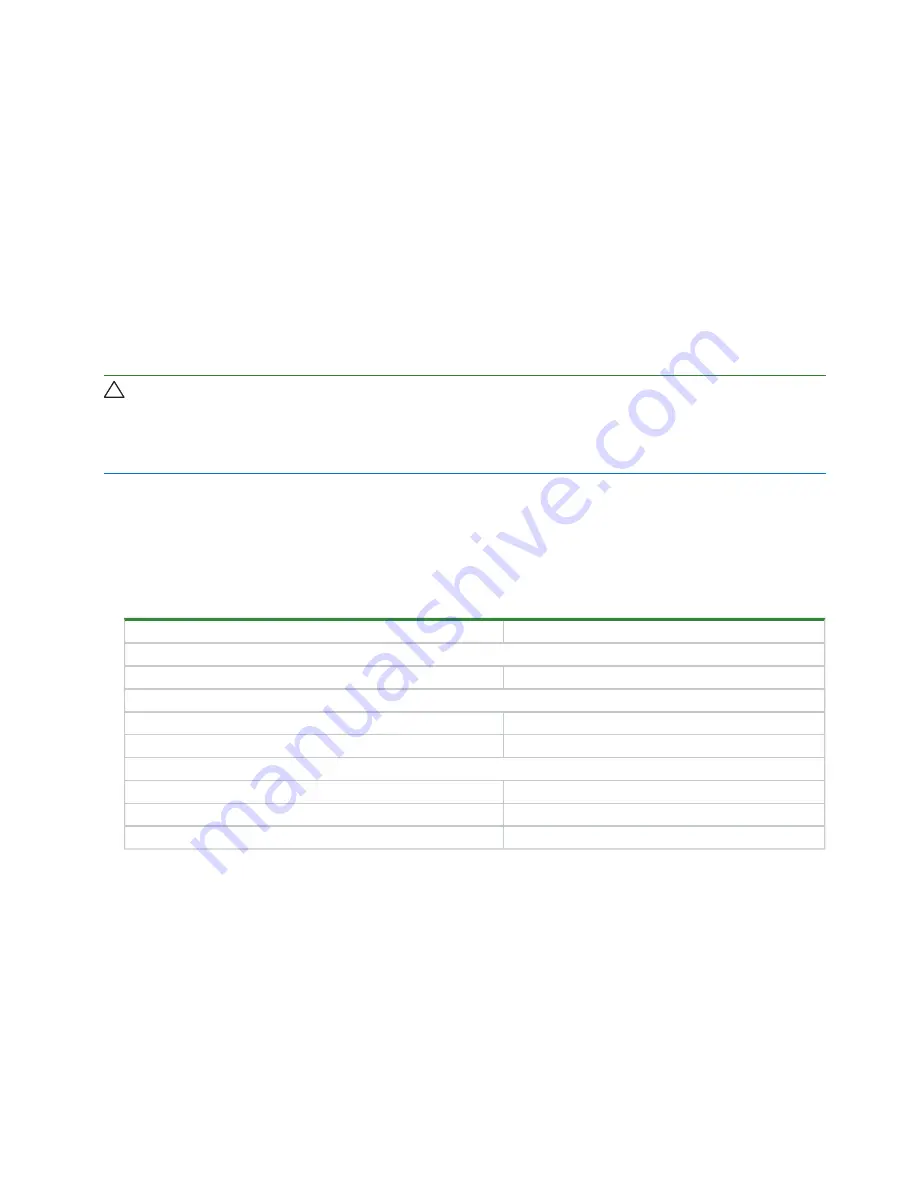

Defective FRU

Replacement time limit

Front panel area

Drive, LFF or SFF, in carrier (DDIC)

5 minutes

Rear panel area

Power cooling module (PCM)

5 minutes

Controller module (CM)

5 minutes

Attachments

Rackmount rail kit

N/A

Cable kits: Standard HD mini-SAS to HD mini-SAS (SF-8644)

N/A

AC power cord, compatible

N/A

Table 17 2U enclosure time limits for FRU replacement

3. Prevent electrostatic discharge from damaging the storage enclosure or its components.

a. Keep a static-protected work surface clear of clutter, including plastic, vinyl, and foam.

b. Transport and store FRUs in static-safe containers.

c. Keep FRUs in their containers until reaching a clear, static-protected work surface.

d. Always wear a grounded ESD wrist strap that meets a minimum 1 megohm (± 10%) resistance standard

and that is snug against your skin.