QF1200S; edition 2016-05; page 13 of 24

4. Maintenance/Servicing of the QF 1200S

Due to the robust construction the Quattroflow pump are widely maintenance-free. The ball bearings

do not need any extra lubrication.

The diaphragms, valves and o-rings should be checked in regular intervals and if needed they has to

be replaced (Service kit diaphragm-valves-o-rings: PSKITQF12MU). We recommend the following

maintenance intervals for the different pump parts:

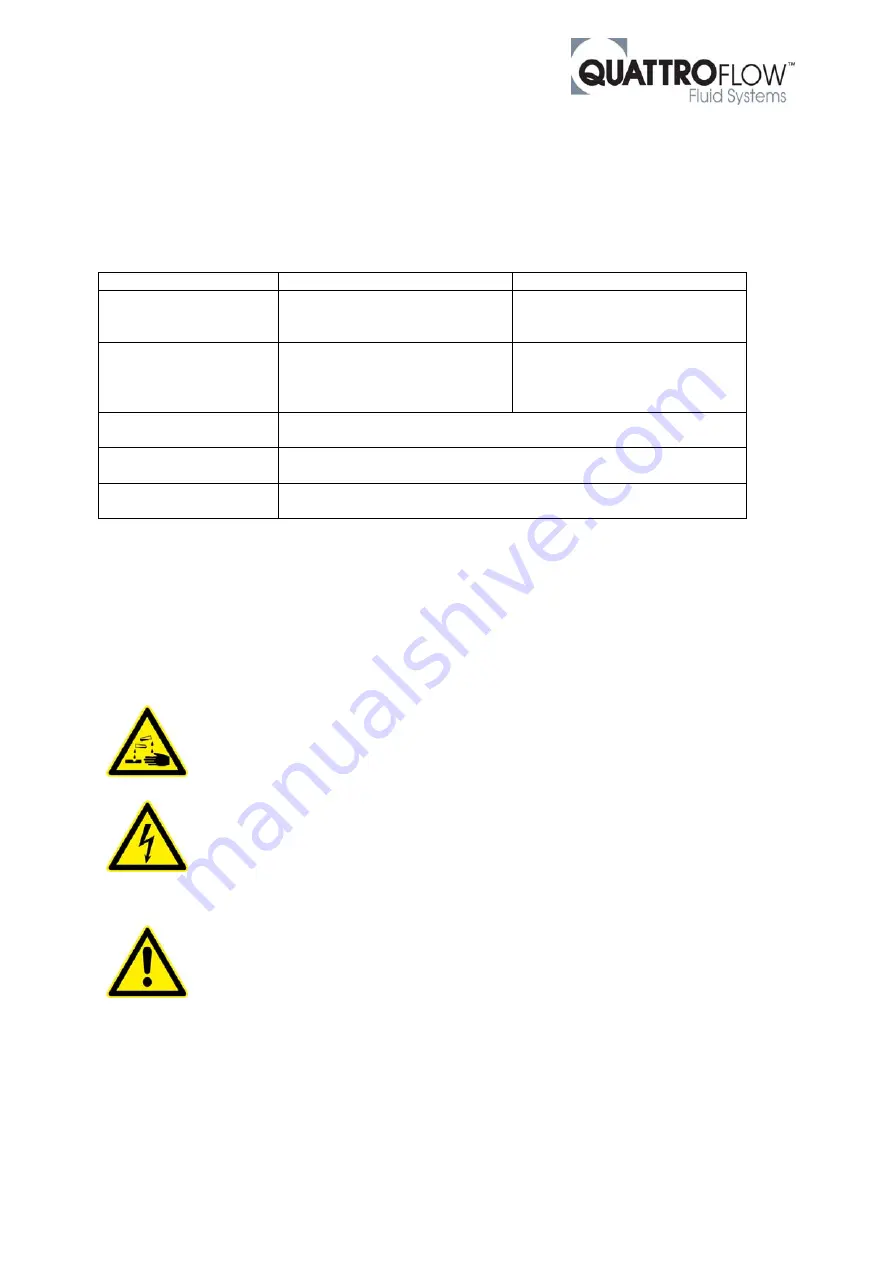

Component Maintenance

interval

Action

Elastomer parts

(diaphragm, valves, o-

rings)

1000 h operating hours,

at least once a year

Replacement of the elastomer

parts (order no. PSKITQF12MU)

Shaft-bearing-cap unit

1000 h operating hours,

at least once a year

Replacement of the complete

unit (kit order no.

PSKITWLC123, PSKITWLC125

or PSKITWLC125-CV)

Motor

Pay attention to the maintenance information of the manual of the

motor

Coupling

Pay attention to the maintenance information of the manual of the

coupling

Gear

Pay attention to the maintenance information of the manual of the

gear

Depending on the operation conditions (pressure, temperature, flow rate, SIP, etc.) it may be

necessary to shorten the maintenance intervals for the elastomers significantly.

In case that the diaphragm broke it needs to be replaced. Then it is also recommended to check the

ball bearings. For corrosion reasons or a clearly audible operating noise the parts of the bearing

service kit should be also replaced. In general it is recommended to replace the elastomer parts

whenever the pump chamber is opened.

Please follow the general guidelines and safety advices when

handling with chemicals

.

Disconnect mains supply before opening the pump housing!

Basically, operations at the pump must be performed during standstill only. The motor

has to disconnect from the power supply, e.g. by pulling out the power plug or using a

repair switch, and has to secure against unintentional switch-on. This can be realized by

a lockable emergency switch. To prevent an accidental re-starting a danger sign should

be installed..

After purging the pump with air there might be a small residual

amount of fluid inside the pump chamber.

Flush the pump chamber thoroughly and check the rinse fluid.

The dismounting and mounting of the pump should be done on a

rigid table or work bench. Please note: the pump is heavy.

All further warning and safety instruction of chapter 3 has to be

respected.