16

Ein15

--, Origin BTN, Stop BTN, Start BTN, Foot BTN, Safe flag-1, Safe flag-2,

Shortcut 266, Lack fault, Block fault, Temp fault, Temp\Feed fault, Upper

CS, Nether CS, Pressure flag

Ein16

--, Origin BTN, Stop BTN, Start BTN, Foot BTN, Safe flag-1, Safe flag-2,

Shortcut 267, Lack fault, Block fault, Temp fault, Temp\Feed fault, Upper

CS, Nether CS, Pressure flag

Kin1

--

、

Upper CS, Nether CS

Kin2

--

、

Upper CS, Nether CS

Kin3

--

、

Upper CS, Nether CS

Kin4

--

、

Upper CS, Nether CS

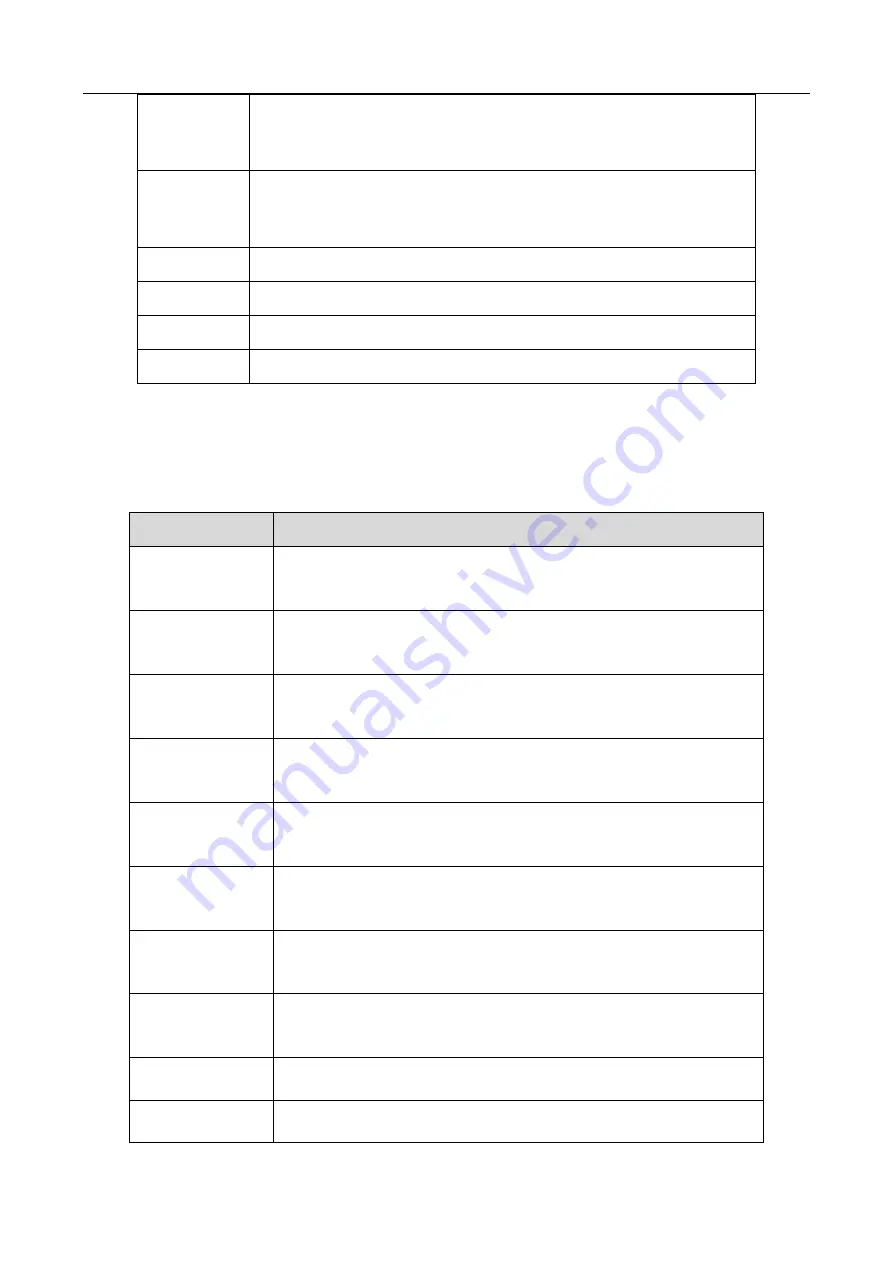

2. In the “Output Config 2” display window, the input interface can be set:

Output Port

Optional Function

Mout1

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4, Working Flag, Work End

Flag, Cylinder, Clean Output

Mout2

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4, Working Flag, Work End

Flag, Cylinder, Clean Output

Mout3

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4, Working Flag, Work End

Flag, Cylinder, Clean Output

Mout4

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4, Working Flag, Work End

Flag, Cylinder, Clean Output

Mout5

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4, Working Flag, Work End

Flag, Cylinder, Clean Output

Mout6

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4, Working Flag, Work End

Flag, Cylinder, Clean Output

Mout7

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4, Working Flag, Work End

Flag, Cylinder, Clean Output

Mout8

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4, Working Flag, Work End

Flag, Cylinder, Clean Output

Eout1

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4

Eout2

--, Nozzle 1, Nozzle 2, Nozzle 3, Nozzle 4