Mod. 0992/0992P

Rev. 00

3. DESCRIPTION

3.1 Characteristics

The machine comprises a boiler for dispensing coffee

and a boiler for producing hot water and steam.

The body of the machine is composed of a stainless steel

load-bearing structure.

3.2 Safety

The coffee boiler has a mechanical overpressure spring

valve calibrated to 10 bar, as well as a thermal protector

that shuts off the heat in case of failure.

The steam boiler has a safety valve calibrated to 2.3 bar

and a thermal protector that shuts off the heat in case of

failure.

The pump has a thermal protector with automatic reset

that protects it in case of overheating.

All heating components and those subjected to electric

voltage are located inside the machine’s panels.

3.3 Vibrations

The machine comes with rubber antivibration feet.

Under normal operating conditions, the machine does

not generate vibrations that are harmful to persons or

objects.

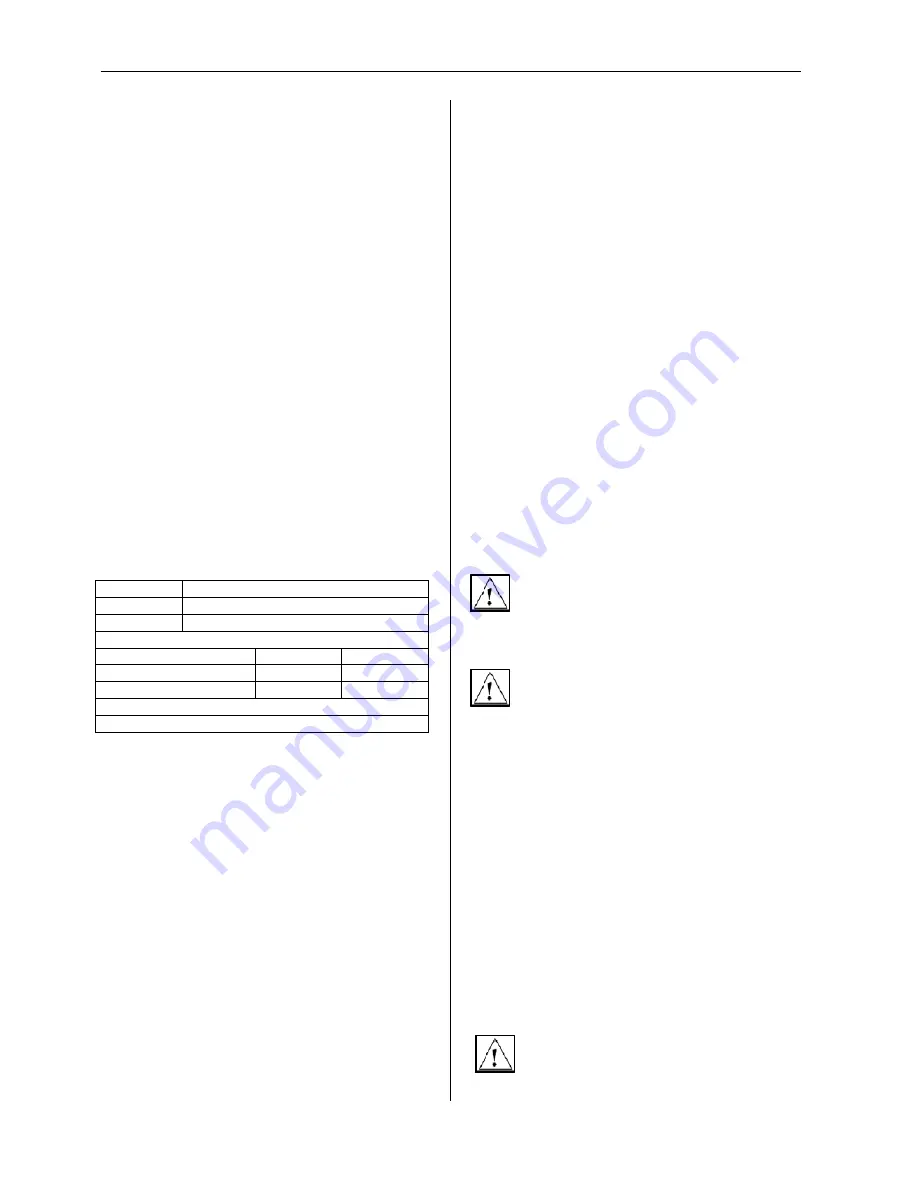

4. TECHNICAL FEATURES

Dimensions

cm L 27 x H 39.5 x D 43.5

In L 10.62 x H 15.55 x D 17.12

Weight

Kg 24.6 (lb 54.23)

Ratings

Power supply voltage

Power

Current

110/120 V - 60 Hz

1700 W

14 A

220/230 V - 50-60 Hz

1700 W

7.3 A

Water tank capacity 3 L

Ambient operating temperature +5° +45° C

5. LEGEND (Fig. 1)

1 Main switch (ON/OFF)

2 Water and steam boiler switch

3 Machine ON green indicator light

4 Steam boiler ON green indicator light

5 Coffee boiler heating element ON red indicator light

6 Steam boiler heating element ON red indicator light

7 Coffee dispensing handle

8 Filter holder

9 Coffee boiler pressure gauge

10 Steam boiler pressure gauge

11 Hot

water

valve

12 Water

nozzle

13 Steam

valve

14 Steam nozzle

15 Drip

tray

16 Digital

thermostat

17 Adjustable valve (Fig. 2)

18 Water tank (Fig. 2)

6. INTENDED USE

This machine was designed and built to dispense coffee

and prepare hot drinks (tea, cappuccino, etc.)

Any other use should be considered inappropriate and

thus dangerous.

The operator should always follow the operating and

maintenance instructions found in this instruction

manual.

In case of doubt or operating defect, stop the machine;

do not carry out any repairs or direct interventions but

contact an authorised service centre.

The operator should never:

touch the hot surfaces with his/her hands but only use

the proper controls;

carry out maintenance operations or transport the

machine when plugged in and hot;

unplug the machine by pulling on the power cord;

use the machine if the power cord is damaged;

touch the machine with wet or damp hands or feet;

turn the package and the machine upside down or lay it

on its side.

wash the machine with direct or high-pressure water

jets or with steam;

immerse the machine in water or other liquids;

use the machine when there are minors in the

immediate vicinity;

let incapacitated persons or minors use the machine;

set containers holding liquids on the machine.

If the machine is wet or very damp, do not

proceed with installation and operation until you

are sure that it has been dried completely.

In any case it is necessary to have a precautionary check

carried out by the service centre to determine if the

electrical components have been damaged.

Contraindications for use

The machine should only be used as intended and not for

other purposes, for example to grind and dispense

products other than coffee or non-food items.

7. TRANSPORT

7.1. Packing

During transport, always keep the package in the correct

position as indicated on the outside of the carton.

Do not turn the package upside down or lay it on its side.

The package contains the detached parts and the

accompanying documentation, which should be kept for

future consultation.

Open the upper part of the package, remove the

accessories and then remove the machine from the

wrapping.

Make sure that the machine, the accessories, the power

cord and the plug are in good condition; if you see

any signs of damage, promptly notify the retailer.

Do not leave packaging items (plastic bags,

expanded polystyrene, nails, cardboard boxes,

etc.) within the reach of children as they are

potentially hazardous.

8

8