Quick-Ohm Küpper & Co. GmbH

Components – Heat Management – Industry Ceramics

- 3 -

User Manual English Controller QC-PC-CO-CH1 20181122

area is contacted with the environment intensively. That implies that by the usage of a heatsink

the surface gets enlarged multiply to establish the needed contact with the ambience. The size of

this heatsink and the impeccable bonding between Peltier element and heatsink on the one side

and between Peltier element and heating and cooling plate, respectively, on the other are the

basic conditions for the determination of the performance of their setup. If you always focus on

that basic structure, your results will be successful. Please visit the category

Know how

in the

section of the heat management on our website indicated below to deepen your knowledge.

Here you find tips and information in a comprehensible and visualized layout.

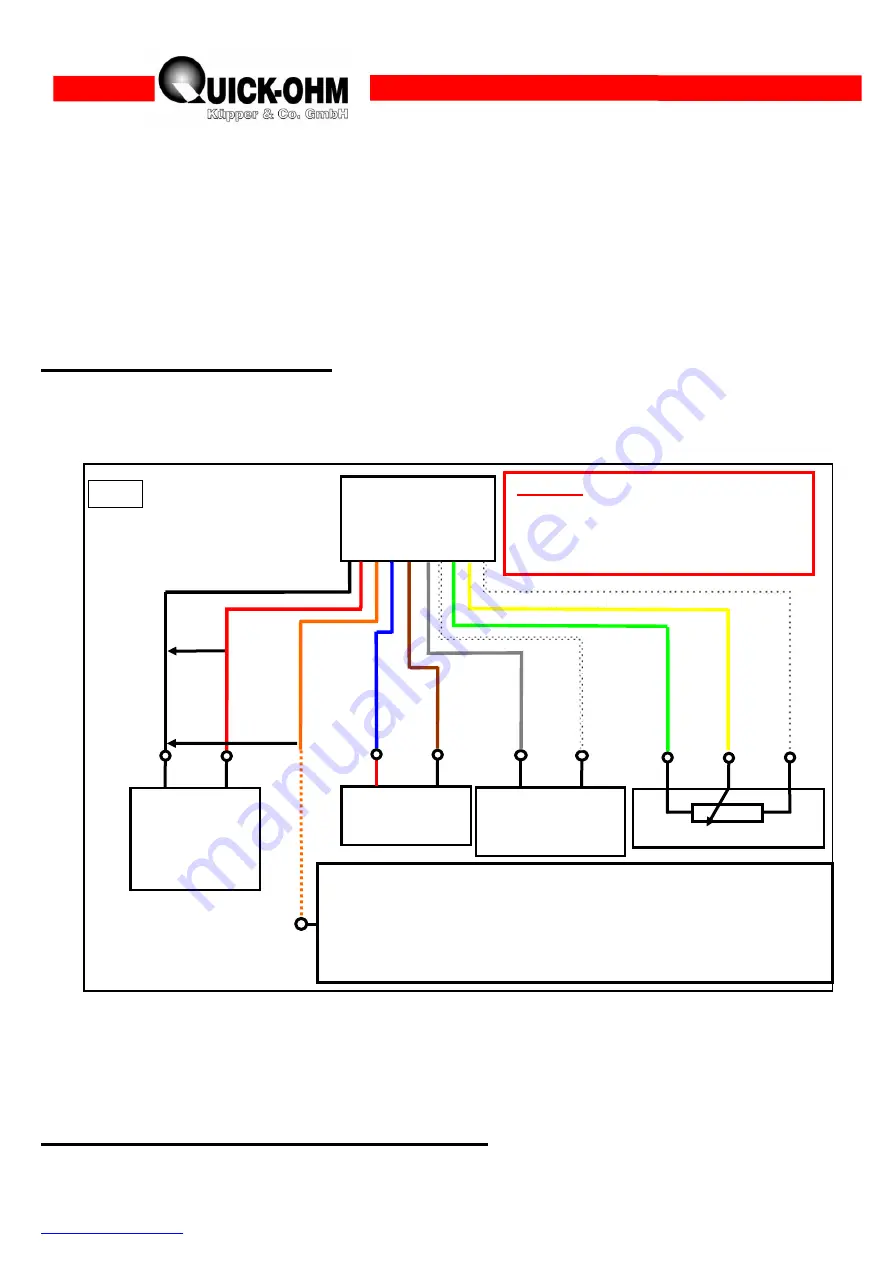

3. The electrical setup:

The wiring of the single components with the controller requires basic knowledge of electrical

engineering and has to be conducted by a qualified person.

To run the controller, a source of direct current voltage is necessary. Sources in the range of 12VDC

to 24VDC are usable. The controller has a separate power input for the supply of the Peltier element

available. The zero potential of both voltage sources is merged on the black wire. Thus, the control

supply and the Peltier supply can either be separated or alternatively connected.

4. Adjusting the control parameter:

Controller

QC-PC-CO-CH1

-

+

Supply

voltage

12V … 24V

Peltier element

Temperature sensor

NTC 10KΩ

β = 3977K

Potentiometer 10KΩ

Fig. 3:

White

Poti max

Yellow

Control

Poti-Signal

Green

Poti min

Grey

Sensor

signal

Brown

-

PE

Blue

+

PE

Black

GND

Red

12..24V

White

+2,5V

Supply voltage Peltier element:

Option1 (one power supply):

Jumper to red

Option2 (two power supplies):

Jump minus of both power

supplies and lay orange on

plus

Orange

U-PE

3…48

VDC

Attention:

After switching off the supply

voltage internal capacities can hold the voltage

for five more minutes. Please make sure that

you don’t tough any connection in the circle

for that time.