13

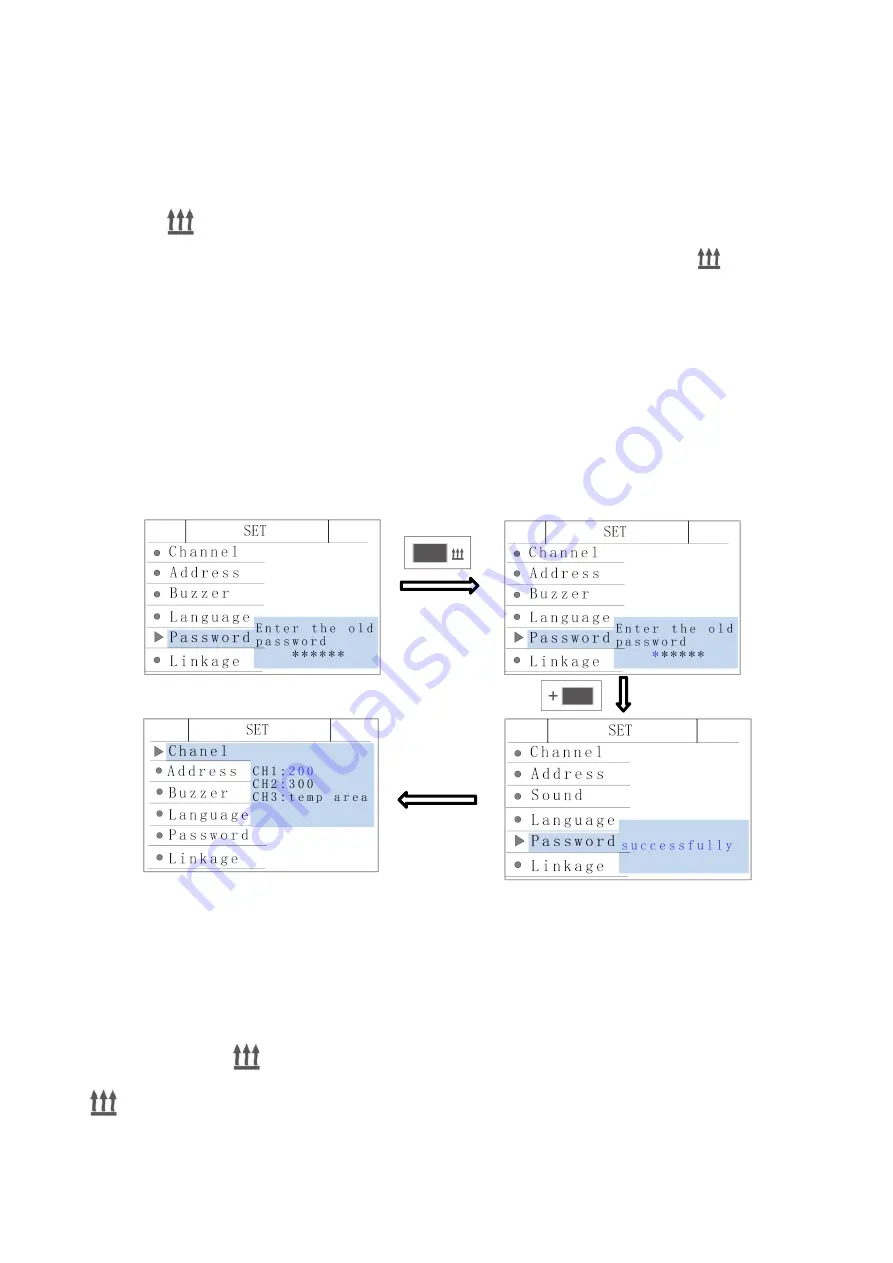

7.2.5.Password Setting

1) Press + or - key in the main menu bar to switch to

“

Password

”

.

2) Press

key to input the old password (Default 000000) and then enter the new

password input interface. Press + or - key to change the value and press

key to

confirm each value entered.

3) After the new password is input successfully, the setting interface will display "Set

Successfully", and then directly go back to the channel menu.

4) The new password takes effect after shutdown and restart or back to the main

interface.

7.2.6. Linkage Setting

1) Press + or - key on the main menu bar to switch to

“

Linkage

”

.

2) Double press

key to select

“

M1

”

(Mode 1) and M1 will turn blue. Then press

key to confirm.

Summary of Contents for 870D

Page 6: ...4 5 Product Specifications 5 1 Dimensions Unit mm...

Page 12: ...10...