KT1~KT5: the testing temperature on the PCB with the outer K-type sensor 1~5

KTC: The real temperature of the top sirocco heater

KTB

:

The real temperature of the bottom sirocco heater

TIR

:

The setting temperature of bottom infrared heater

KIR

:

The real temperature of the bottom infrared heater

TOH

:

Top sirocco heater is in working mode or not

BOH

:

Bottom sirocco heater in working mode or not

IRH

:

The infrared heaters are in working mode or not.

BUM

:

Pump is in working mode or not

FAN

:

The nearside cooling fan is in working mode or not

HED

:

the position of the top heater

(

UP-DOWN-UNKN

)

ALG

:

the position of the contraposition arm

(

IN-OUT-UNKN

)

SUC

:

the position of the nozzle

(

UP-DOWN-UNKN

)

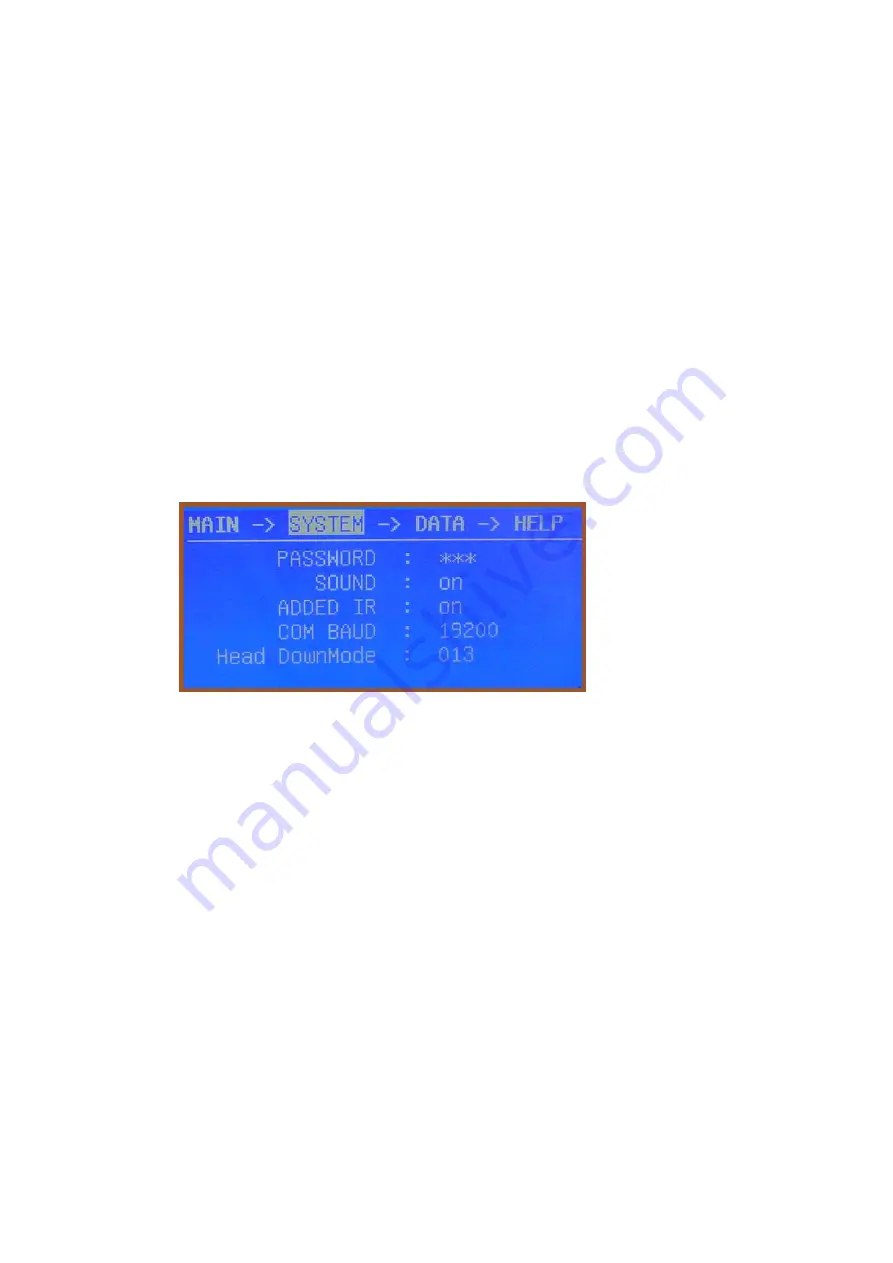

SYSTEM INTERFACE:

PASSWORD

:

Set password for protecting the parameter setting.

SOUND

:

Alarming or not (ON: with alarming when happening abnormal.

OFF: without alarming when happening abnormal.)

COM BAUD

:

Set the communication baud rate and the default value is 19200.

HEAD DOWN MODE: When the value is “0”, the heater head adjusts automatically the distance between it

and the chip when touching the chip. When the value is not “0”, the value is the

downward moving distance of the heater head.

The parameters in the data interface can be set in the

advanced interface of the BGA software

. The

PASSWORD

’s

function is same with

“protected parameter”

of the software and

COM BAUD

also can be set in the

“communication option”

of the software. The

Head DownMode

can be set in the “

the mode of heater head

running down

”.

DATA INTERFACE

:

2100 has ten working modes in which parameter can be changed according to demands.

In data interface, all the parameters of the ten working modes can be changed according to demands.

Flow0~Flow9:

which means the different working modes.

T0:

Valve temperature and T0

≤

TIR.

TD1~TD7:

which means the heating temperature in the different zone (D1~D6&COOL) of the top hot air.

BD1~BD7:

which means the heating temperature in the different zone (D1~D6&COOL) of the bottom hot air.

Page 3

Summary of Contents for BGA2100

Page 1: ...QUICK BGA 2100 ...