ENGLISH (110-501)

110

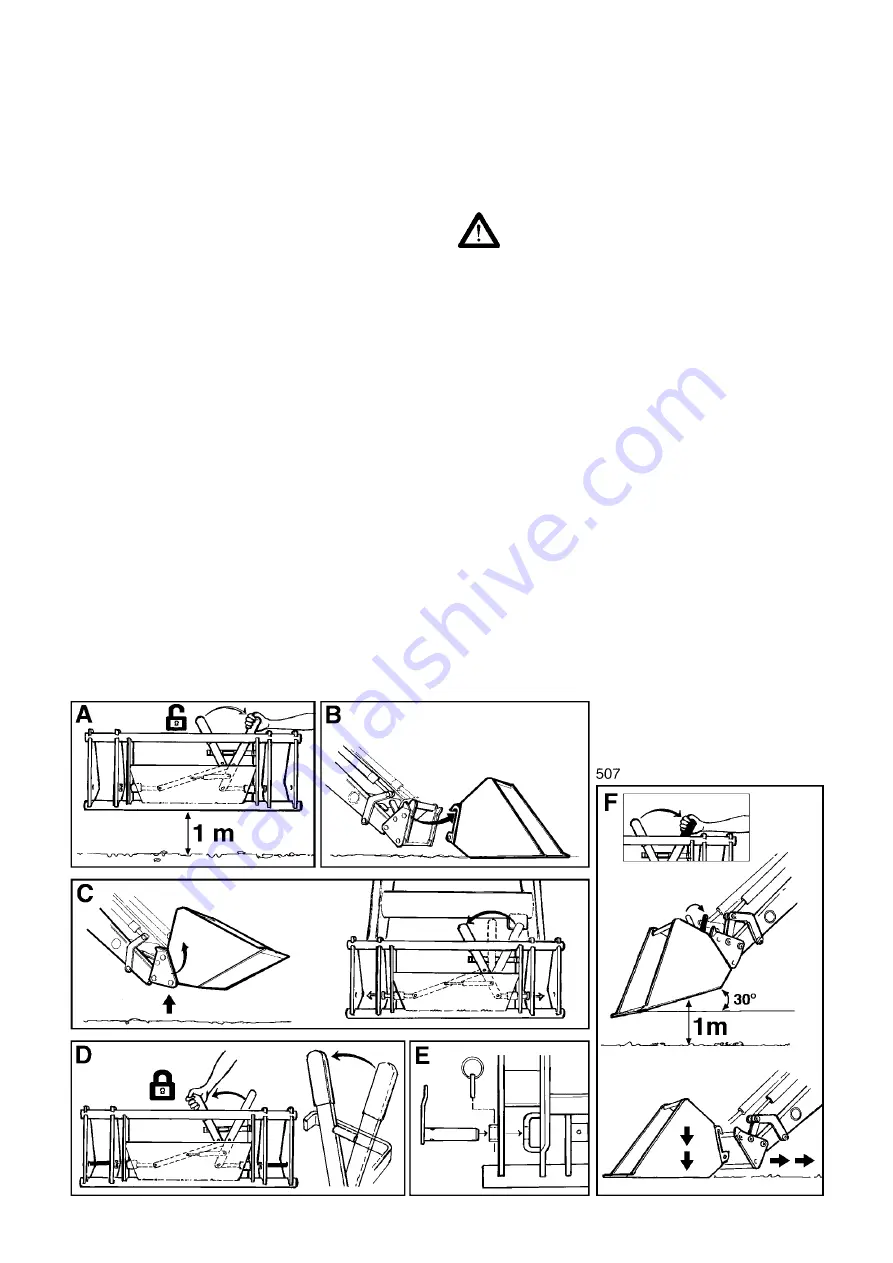

ATTACHING OF IMPLEMENTS

- Move the locking lever in open position (left). This will

be easier if the loader beam is lifted, approx.1 m

(illustr.A).

- Lean tool carrier slightly forwards.

- Drive the loader towards the implement until the

implement hooks hitch the tool carrier (illustr.B).

Loaders with tool carrier EURO (8) and EURO-

COMBI

(CLICK-ON)

- Lift (approx.1 m) and crowd the implement. The

locking lever will be disengaged and the implement

automatically locked (illustr.C).

Loaders with tool carriers equipped with

manual locking

- Lift and crowd the implement. Lock the

implement by moving the lever to the right (illustr.D).

Loaders with tool carriers equipped with loose

latch bolts

- Lift and crowd the implement. Install the bolts and

secure with locking pins (illustr.E).

REMARK ! See the Mounting Instruction for the

hydraulic locking of implements

DETACHING OF IMPLEMENTS

Fig.F

- Lift the implement approx. 1 m.

- Lean the implement approx. 30° forwards.

- Move the locking lever to the left and remove the latch

bolts.

- Lower the implement to the ground. Reverse tractor.

Always check, when changing implements, that the

implement is properly locked in position by pushing the

front part of the implement against the ground.

WARNING

An implement of another origin than ÅLÖ may cause

damage to the loader. Therefore never fit an implement

of another make without making sure that the implement

is approved by ALÖ.

Summary of Contents for Q 900 Series

Page 171: ...125 125 501...