ENGLISH (118-501)

118

1

2

DRIVING INSTRUCTIONS AND MAINTE-

NANCE

For maximum stability and to avoid skidding, always

carry implement with load as low as possible.

When driving the implement into the material to be

handled, always make sure that the valve is in a neutral

position, otherwise the front of the tractor tends to rear

at the moment of drive-in, which would entail strains on

both loader and tractor. Keep to the following rules:

NEVER drive at full speed into the material. Select a low

gear for the best traction.

COUNTER WEIGHT: For overloading and safety

reasons, always use counter-balance with weights when

carrying heavy materials or implements with large out-

reach.

See safety instructions, page 105.

Do not leave the tractor with the loader in ”lift” position

and do not stand beneath the load.

When changing implements, always check that the

implement is properly locked in position by pressing the

front end of the implement to the ground.

OPERATING

Applies to loaders with separate control valve

(ERGO DRIVE).

For loaders with ELECTRO-hydraulic mono lever remote

control (ELECTRO DRIVE), see the separate instruction

for this equipment !

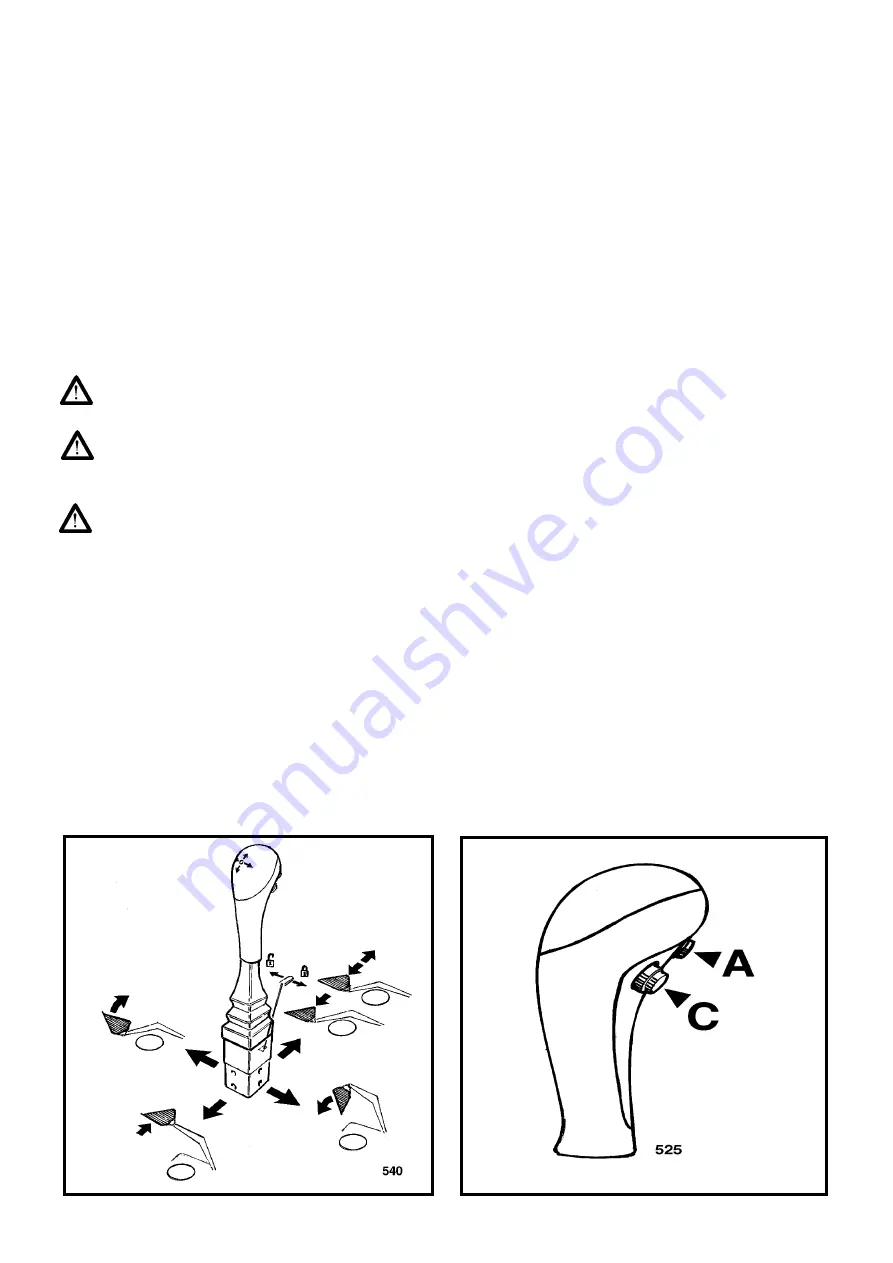

The control device (MONO-lever) has the following

functions:

Lever Movement:

Backwards -

Loader beam is lifted

Forwards

-

Lowering of loader beam + floating

position*

Left ** -

The implement is crowded

Right **

-

The implement is dumped

*The floating function is engaged when the control

device is brought maximally forwards. The lever should

then stay in this position. By moving the lever in the

reverse direction, the function will be disengaged.

** Concerns right-hand mounted control device. As

regards the left-hand mounted control device, the

reversed lever movement is obtained by shifting the

hydraulic hoses marked yellow-red. See the instruction

supplied with the hydraulic kit.

Safety Locking Device: The control device is equipped

with a safety lock, see fig.1, which, in locking position

(left), prevents involuntary operation.

Selecto (applies to loaders equipped with electric switch

valves)

The lever knob is equipped with two switches acc. to

fig.2.

Function

Control lever in operating position for implement func-

tion.

Push button (A) = Valve (3rd) in function

Push button (C) = Valve (4th) in function

Remark

If hydraulic implement locking is fitted, see the instruc-

tions for this equipment.

Summary of Contents for Q 900 Series

Page 171: ...125 125 501...