119

ENGLISH (119-501)

1

2

DRIVING INSTRUCTIONS AND MAINTE-

NANCE

LEVEL INDICATOR

The loader is equipped with a level indicator, which gives

the angle of the implement relative to the ground, when,

for example, handling pallets. See "Loader, Mounting".

PARALLEL DEVICE

If the loader is lowered or the implement is dumped at

low engine speed, the loader rams may not be totally

recharged, which could lead to the following:

- that the loader beam is lifted if the implement is fully

crowded at ground level.

- that the implement rams get slightly compressed,

which means that you won't have total control of the

implement.

Therefore, make a practice of either increasing the

engine speed when lowering or dumping the implement,

or keeping the control device in operating position until

the implement rams have been recharged (especially

concerning tractors with a low oil flow).

VARIABLE LIFTING HEIGHT

Fig. 2

When an increased lifting capacity is required, move the

lift rams to the lower mounting holes in the bearing box

of the loader (concerns certain loader models).

SCREW UNIONS

Check, after some days’ initial use, that all nuts and bolts

are tightened, especially where the subframes are

secured to the tractor body.After that we recommend

controls at regular intervals in connection with the

maintenance / service of the tractor.

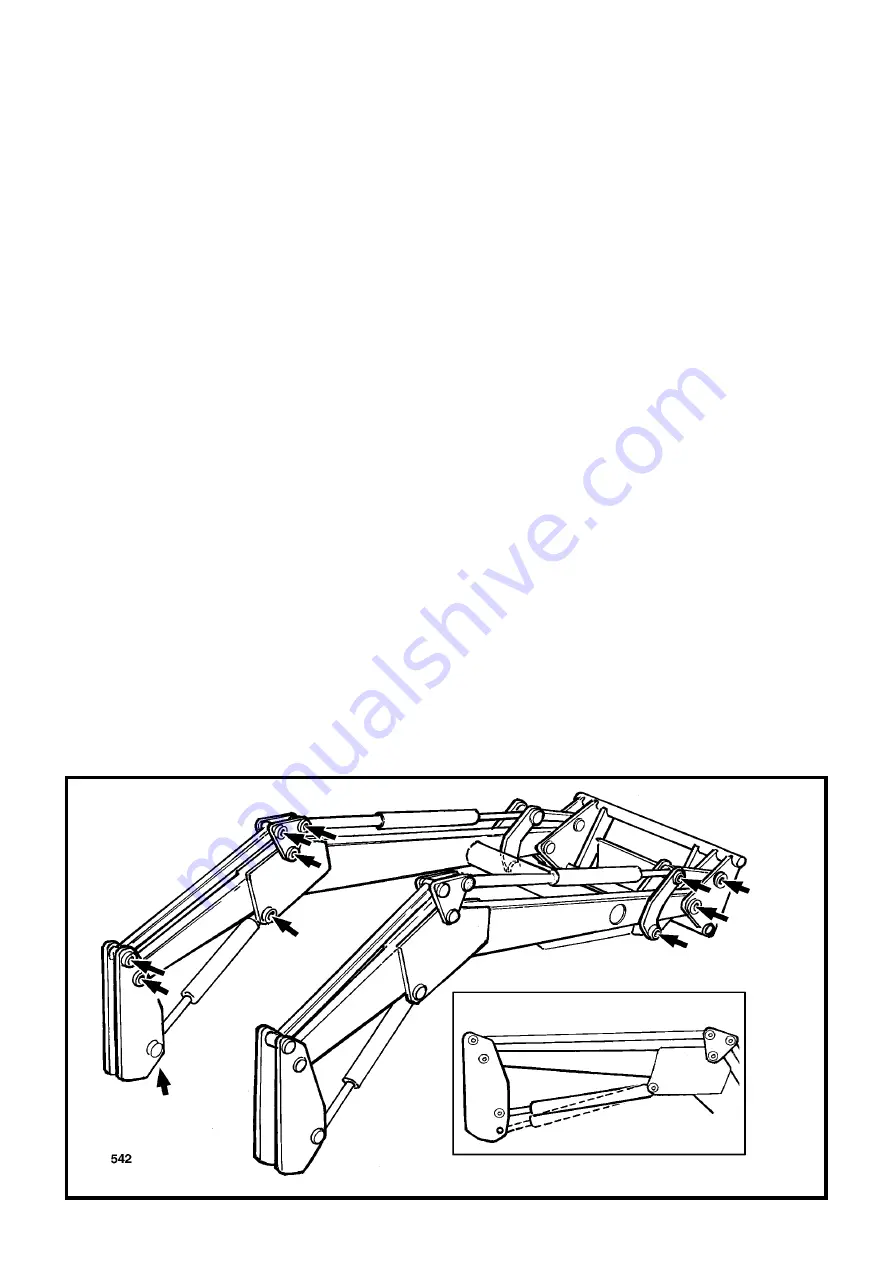

GREASING:

All lubricating points (fig.1) are equipped with greasing

nipples and should be greased at least once a week on

regular use (use lubricating grease, type B.P.

Energrease L.S.-EP2, or equivalent.)

CLEANING

Always keep tractor and loader clean, in particular the

loader rams and valves. When using a high-pressure

water gun, please avoid spraying water directly on valves

and control device.

When disconnecting the loader / the implement, don’t

forget to put dust-caps on the quick-couplings. If you

don't, dirt may get inside the hydraulic system, which will

cause damage and expensive repairs.

OTHER NOTES

Do not forget to check the level of the hydraulic oil and to

change oil and filters regularly as prescribed by the

tractor manufacturer.

Cold and dirty oil will increase the time for the lift- and

implement movements of the loader.

Summary of Contents for Q 900 Series

Page 171: ...125 125 501...