115

ENGLISH (115-501)

F

CONNECTION / DISCONNECTION

Make sure, when disconnecting imple-

ments, that the bucket rams NOT are in end

position (disconnection under pressure may

cause problems when connecting).

Fig. F

Connection

- Clean the surfaces carefully of loader-and implement

parts.

- Fit the dowels of the implement part into correspond-

ing holes on the loader part (A).

- Make sure that the lever grips the implement part (B)

and move lever backwards until the lever is secured.

- Always when connecting check that the lever is

locked.

Disconnection

- Push button C and move lever forwards.

- Remove the implement part and hitch on to the

implement.

Move the lever to locked position for protection

( IMPORTANT).

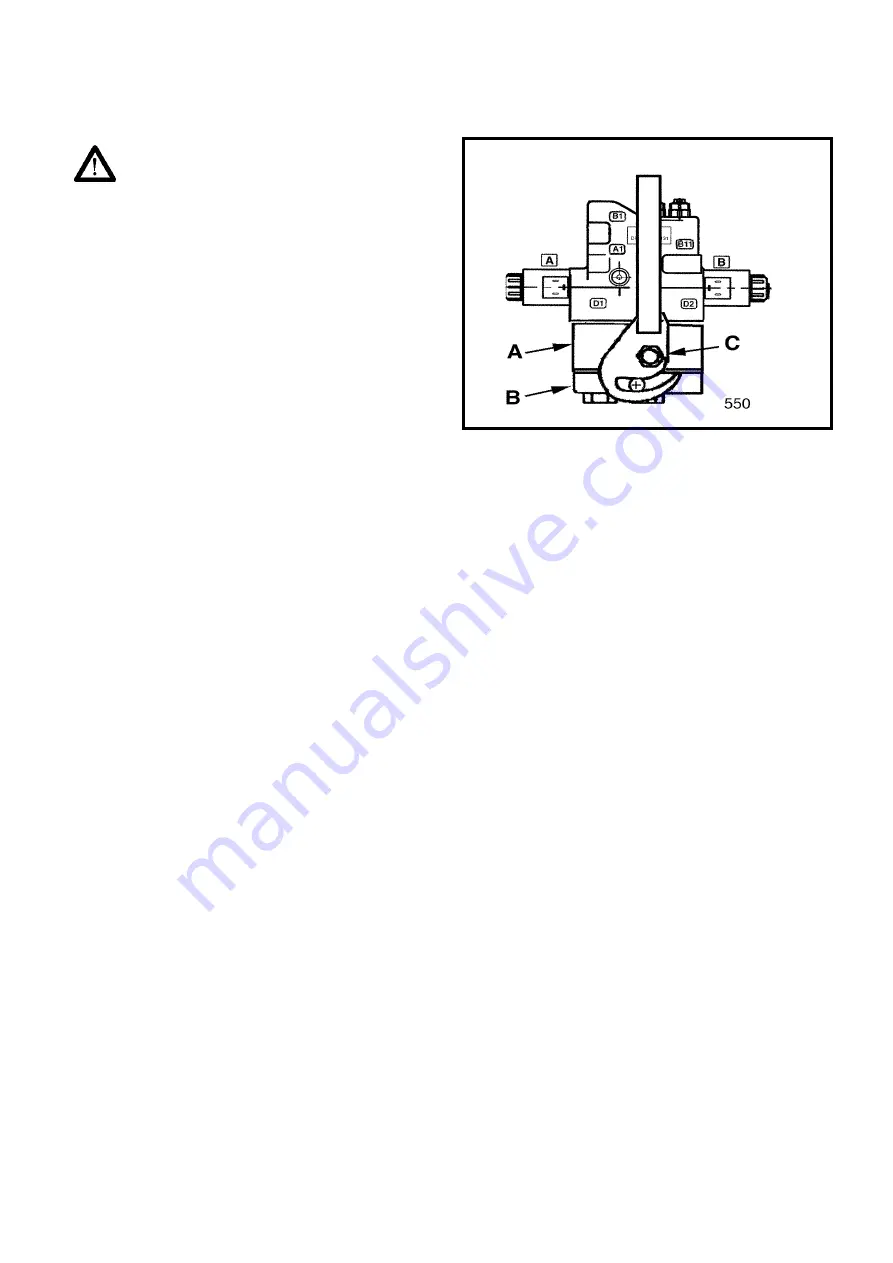

SPECIFICATIONS

Dimension of quick couplings: 3/8"

Oil pressure: max. 200 bar (the total pressure on all

couplings (2 or 4).

MAINTENANCE

Always when connecting, clean the surfaces of the

loader - and implement parts carefully.

Oil leakage

The quick couplings may get damaged, either due to

impurities ( not cleaned surfaces before connection) or

due to an exceeding of the max. allowed oil pressure

(200 bar). If this is the case, locate the leaking line and

exchange the damaged coupling - see the spare parts

sheet.

ATTENTION

Faulty use or maintenance of products aimed for high oil

pressures may cause serious damages. It is therefore of

the utmost importance that the instructions are followed

and that damaged or worn out parts are immediately

exchanged.

Summary of Contents for Q 910 US

Page 171: ...125 125 501...