ENGLISH (120-501)

120

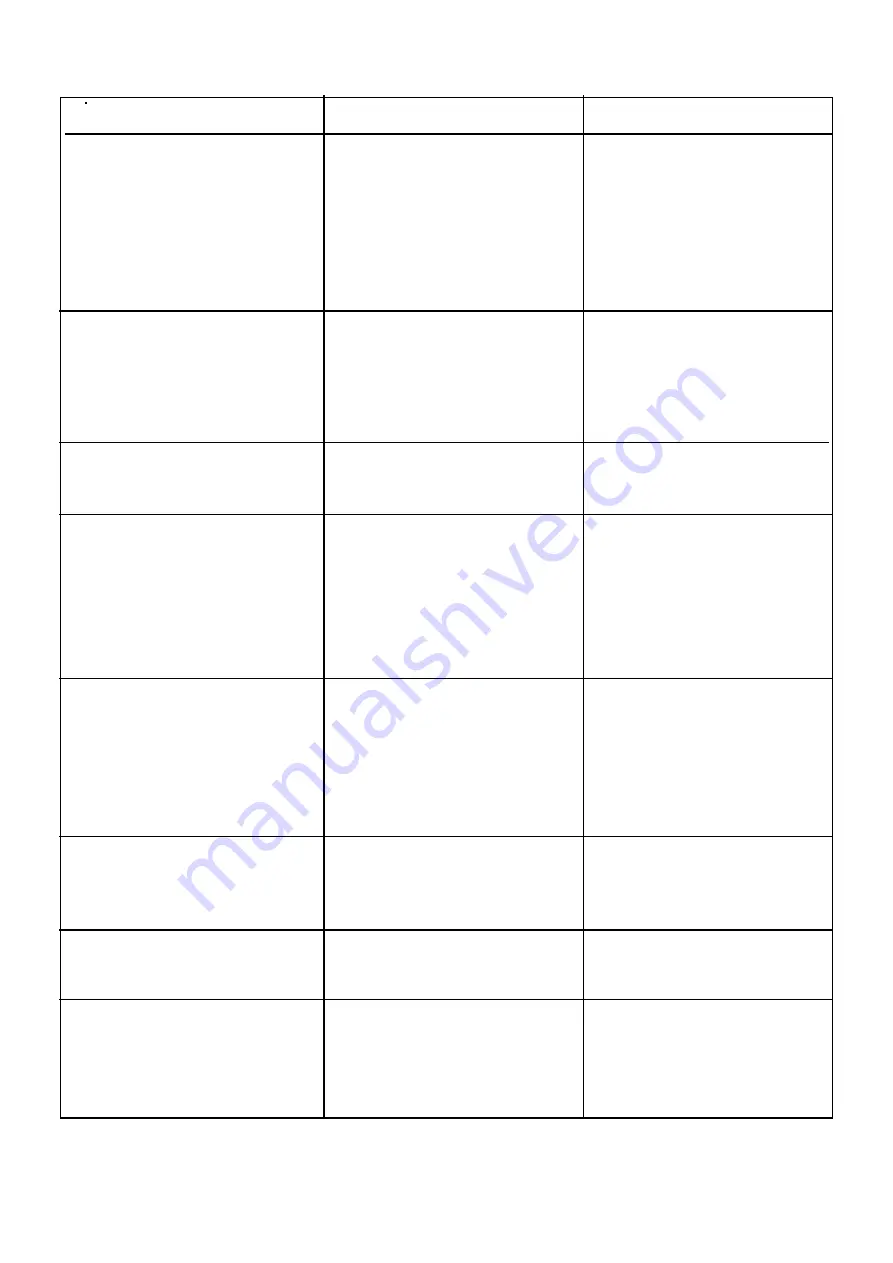

TROUBLE

CAUSE

REMEDY

* concerns only loaders

with separate control valve

TROUBLE-SHOOTING CHART

Loader does not keep the load

up when the valve is in NEU-

TRAL position

NOTE ! ! there is always a

minor internal oil leakage

(manufacturer's allowance)

Insufficient lifting- or tear out

capacity

The float function of the valve

does not work. The control

cables become deformed

Loader works slowly or is not

moving at all

Difficulty to operate valve

Oil leakage in hydraulic rams

The loader drops a little when

the lifting movement begins

External oil leakage

at valve spools

Leaking security valve

( implement function)

Damaged valve spool (too much

play between spool and hole in

valve housing)

Defective piston seal, see F

Oil pressure too low:

a) Defective oil pump

b) Defective relief valve

See point A: 1,3

Bad connection of control

cable(s)

Too little oil in hydraulic system

Damaged or incorrectly

connected quick-coupling

Faulty connection of hoses

Too small oil flow

Control cables jammed

Defective seals

Damaged piston rod

Damaged bearing / piston

Damaged barrel

Defective check valve

Defective seal

Check by disconnecting ram

hoses from valve

* Change the valve (just

changing seals is not enough)

Check oil pressure

a)before valve

b) after valve

* See the Valve's Mounting

Instructions

Fill up oil according to tractor

manufacturer's instructions

Check the quick-couplings

Connect in accordance to the

colour marking

Check the tractor hydraulics

* Check installation

When changing seals, check

that the damages aren't

caused by 2, 3 or 4

* See the Valve's Mounting

Instructions

* Change seals

(check the return pipe to tank)

1

2

3

1

2

1

1

2

3

4

1

1

2

3

4

1

1

1

2

1

1

1

2

3

4

1

1

1

1

A

B

C

D

E

F

G

H

Summary of Contents for Q 910 US

Page 171: ...125 125 501...