Menu use

UICKO

OLED T12 QUICKO HEATING SOLDERING STATION

SET:300

℃

13%

25

℃

24

V

300

℃

1 -95

T

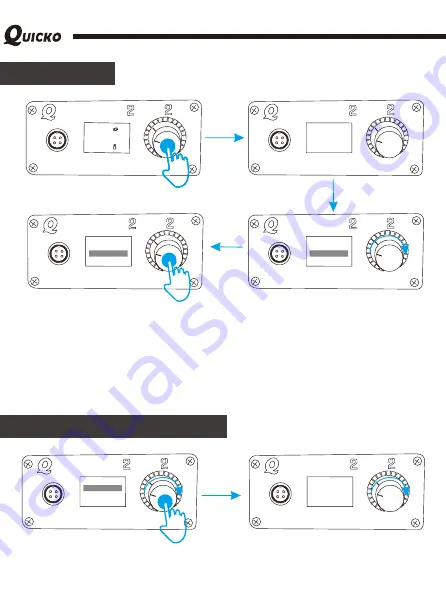

Enter the menu setting interface: under the normal working temperature interface, long

press the encoder button (about 3s). Enter the host setup mode! Exit menu settings

interface: at the menu setting interface, long press the encoder button (about 3s), exit the

host setup mode!

Setting menu:

Enter the function item: rotate the encoder to the corresponding function, and short press

the button to enter the function item.

Exit setting function item: after setting the corresponding parameters with the encoder rotary

knob, short press the button to confirm exit the function item.

UICKO

OLED T12 QUICKO HEATING SOLDERING STATION

1 -95

T

MENU

1.CALIBRATION

2.AUTOSLEEP

3.AUTOPOWEROFF

UICKO

OLED T12 QUICKO HEATING SOLDERING STATION

1 -95

T

MENU

1.CALIBRATION

2.AUTOSLEEP

3.AUTOPOWEROFF

UICKO

OLED T12 QUICKO HEATING SOLDERING STATION

1 -95

T

MENU

1.CALIBRATION

2.AUTOSLEEP

3.AUTOPOWEROFF

Temperature calibration

UICKO

OLED T12 QUICKO HEATING SOLDERING STATION

1 -95

T

MENU

1.CALIBRATION

2.AUTOSLEEP

3.AUTOPOWEROFF

UICKO

OLED T12 QUICKO HEATING SOLDERING STATION

1 -95

T

CURRENT350

℃

RATIO[100%]

After selecting the temperature calibration function, short press the encoder to enter the

temperature calibration setting, the adjustable temperature ratio: 70%-130%, if there is no

professional measurement instrument, please set the ratio value to 100%.