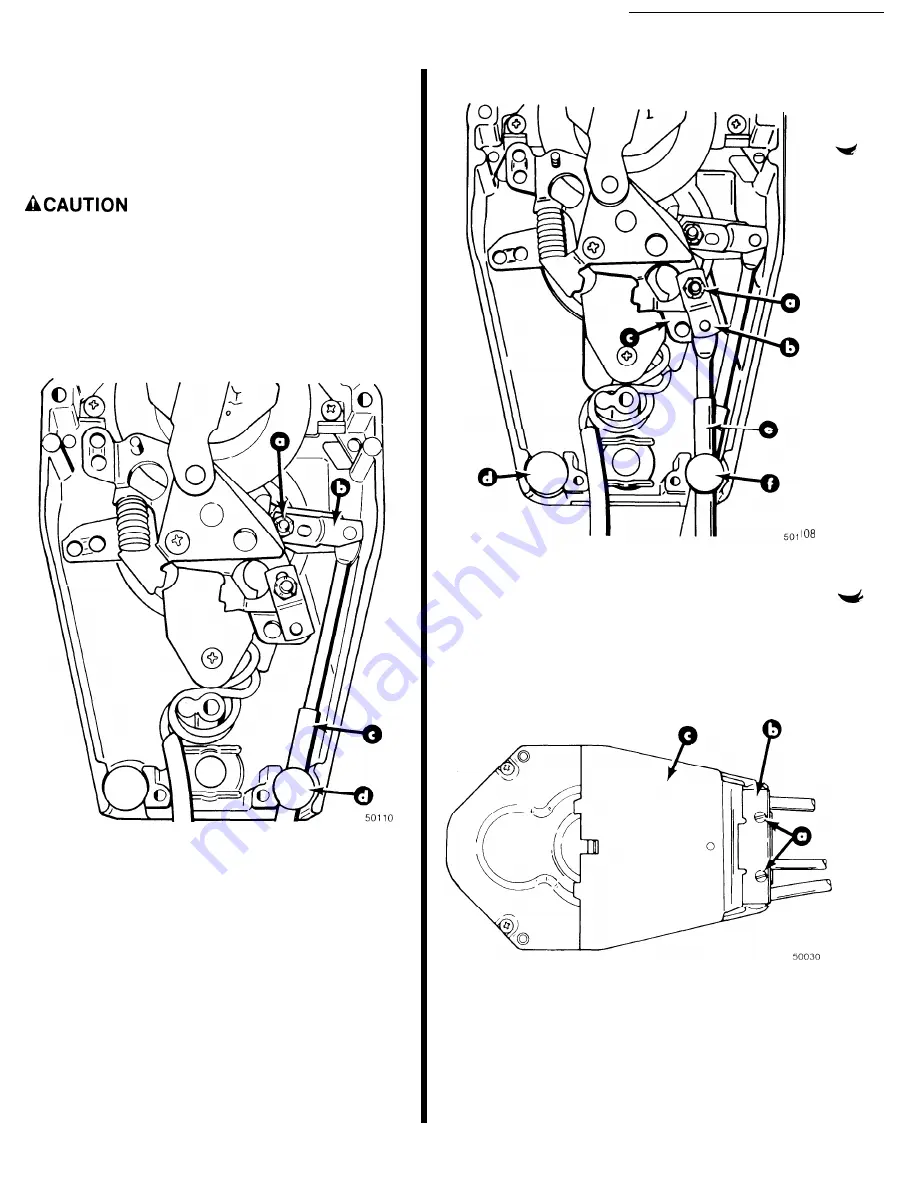

Starboard Side Control

Module Cable Installation

(Outboard Models 250 HP

3.4 Litre and Above)

Before tightening cable fastener locknut, be sure that

pin (on end of cable fastener) is completely thru cable

end and shift/throttle lever. A pin, that is partially thru

cable and lever, may cause fastener to bend when

locknut is tightened.

Shift Cable

a -

Cable Fastener Locknut

b - Cable Fastener

c - Shift Cable

d - Cable Anchor Barrel

IMPORTANT: Cable fastener (b) must be relocated to

position as shown.

Torque shift cable fastener locknut to

20-25

Ibs. in.

(2.3

to

2.8

N.m.)

-6-

Throttle Cable

a - Cable Fastener Locknut

b

-

Cable Fastener

c

-

Throttle Lever

d Spacer (From Parts Bay)

e

-

Throttle Cable

f - Cable Anchor Barrel

Torque throttle cable fastener locknut to 20 to 25 Ibs

in. (2.3 to 2.8 N m

)

a

Screws

b Cable Retainer

C

Access Cover

Position access cover and cable retainer onto back

side of control and secure both to control with 2

screws.

Torque access cover and cable retainer screws

to 60 Ibs. in. (7 N.m.)