7

GB-031AB/f.

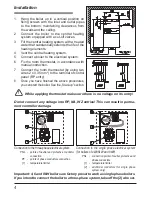

DHW Cylinder thermostat (Tzas entry- refers to EKCO.LN2 and EKCO.L2 model)

–

Kospel suggests to use the VCZMH6000E valve with the VC6013ZZ00 servo-motor. The

three-way valve control is performed by applying 230V on the brown wire or the black

wire (blue is the neutral wire). Voltage on the valve through the brown wire will switch the

valve to a position, where the pass between the „AB” inlet and the „B” outlet gets opened.

Shall voltage be passed to the black wire, the valve will get switched to the position in

which the channel between the „AB” inlet and the „A” outlet will be opened. The „AB”

inlet and the „A” and „B” outlets are marked on the valve An entry „B’’ is to supply the

central heating system and the entry „A’’ is to supply the cylinder. Important. To activate

the cylinder heating please follow the instructions in the „ADVANCED SETTINGS” sec-

tion. Set up the temperature of heating medium (50 - 85°C).

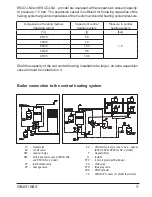

Master appliance (NA entry)

– you can limit the power used, i.e. the boiler can be

switched off while another appliance consumes electricity. To do it, an electrician should

install in line an extra open contact to the NA entry (voltage free entry), so that when a

master appliance gets on, the contact will be opened the boiler switched off. When the

NA contact gets opened, heating will get off and the pump stopped. The EKCO.LN2

and EKCO.L2 model may also work as second boiler. If it is so, the master boiler by

opening the NA entry will stop heating of EKCO. However, the mode of the three-way

valve control stays on so a DHW cylinder is charged by the heat from the master boiler.

refers to EKCO.LN2 and EKCO.L2 boiler only

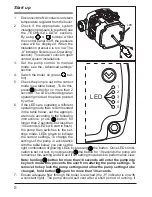

Special start-up procedure (when the system is filled with an antifreeze solution)

A flow rate reading error may occur if you start-up the unit at low ambient temperature.

This error may occur because the physical properties of antifreeze solution. If the H

indicator flickers and the cut-off valves are opened you have to close NA and RP contacts

which will automatically start the special start-up procedure. As a result, the medium will

be warmed up to temperature that enable you to read the flow rate correctly. The duration

of procedure depends on both the installation capacity and the temperature inside the

installation. When a control panel display shows selected parameters alternately and

marks („-”, „--”) it means that the procedure is started. The procedure will close auto-

matically and the unit will start normal operation once the minimal flow rate is reached.