Industrial / Air Master Series

Quincy Compressor

50161-105, March 2008

20

3501 Wismann Lane, Quincy Ill. - 62305-3116

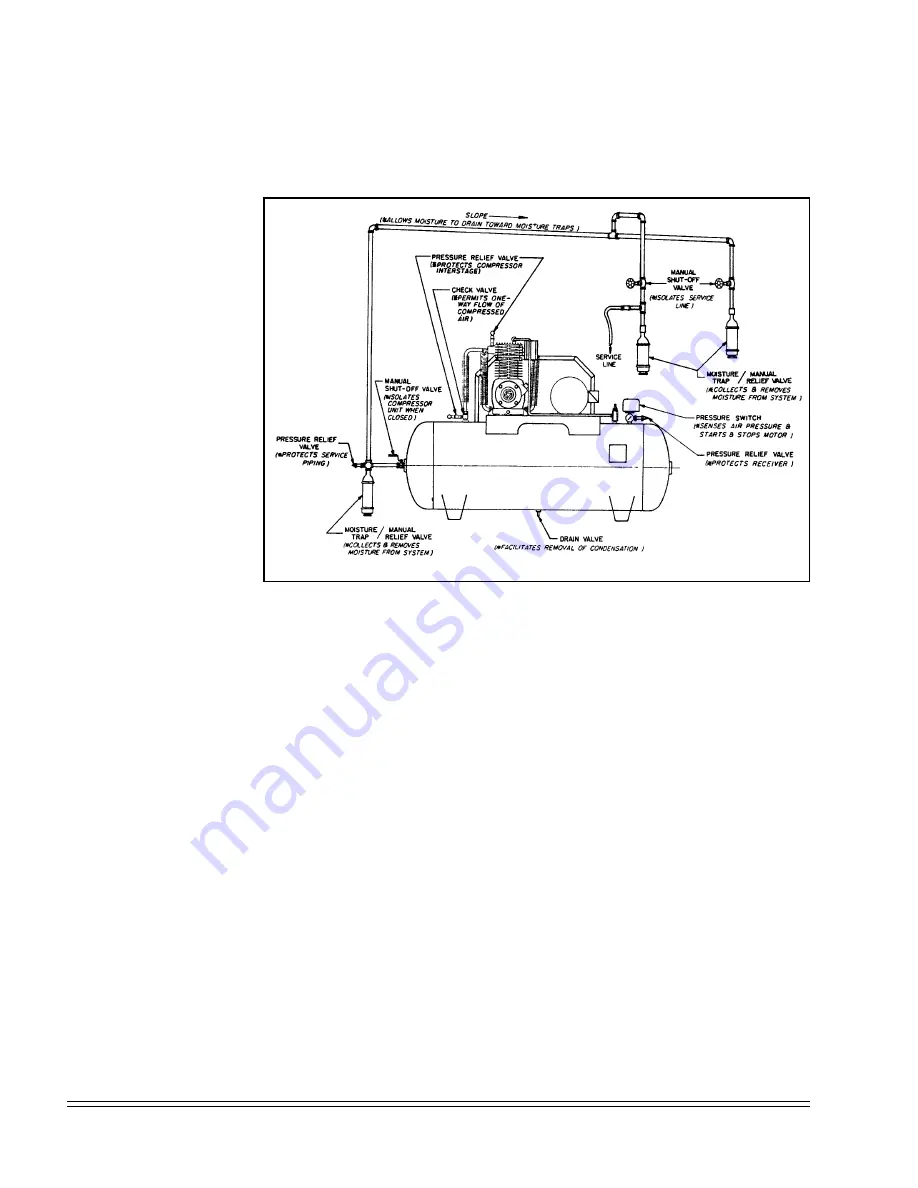

where moisture can be easily removed. All service line outlets should be

installed above the moisture traps to prevent moisture from entering the tool

or device using the air. Manual shutoff valves, protected by pressure relief

valves, should be installed at all service line outlets to eliminate leakage while

the tools are not in use.

As with any piping, all parts of the discharge piping should fit so as not to

create any stress between the piping and components.

Pnuematic Circuit Breakers or Velocity Fuses

The Occupational Safety and Health Act (OSHA), Section 1926.303, Paragraph

7, published in the Code of Federal Regulations 29 CFR 1920.1, revised July 1,

1982 states that all hoses exceeding 1/2" inside diameter shall have a safety

device at the source of supply or branch line to reduce pressure in case of a hose

failure”

These pnuematic safety devices are designed to prevent hoses from whip-

ping and/or the loss of hazardous or toxic gasses, all of which could result in a

serious or fatal accident.

Never join pipes or fittings with lead-tin soldering. Welded or

threaded steel pipes and cast iron fittings, designed for the pres-

sures and temperatures, are recommended.

Pressure Vessels

Air receiver tanks and other pressure containing vessels such as

(but not

limited to)

pulsation bottles, heat exchangers, moisture separators and traps,

must be in accordance with ASME Boiler and Pressure Vessel Code Section VIII

and ANSI B19.3 safety standards. They must be equipped with a properly sized

Fig. 3-8 Typical Drop Leg & Component Location

Pix 1007-004

WARNING !

Summary of Contents for Air Master Series

Page 46: ......