Section V - Operating Instructions

Auto Start/Stop Pilot Valve Operation

The pilot valve is factory set to each user’s

requirement. Only adjust settings if the

requirement was unknown at time of order

or if shop air pressure differs enough from

factory preset to cause the DEFENDER™

to not function properly.

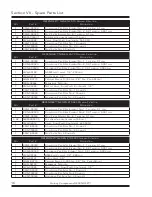

Pilot Valve Adjustment Procedure

There are two screws and two lock nuts on

the pilot valve.

Screw #4 is the cutout pressure (turn

clockwise to increase

and counter clockwise

to decrease). Screw #2

is the cut-in pressure

(turn clockwise

to increase and

counter clockwise to

decrease). Use 1/8”

turn increments when

adjusting screw #2.

Screws #4 & #2 are

interactive to each

other. When one is

adjusted it changes

the setting of the other.

When ever adjusting

the Pilot Valve use

small increments and

keep the differential at 15-20 psig.

NOTICE!

During the adjustment process,

the valve may begin opening and

closing rapidly, this happens when the

differential is outside the designed

pressure range.

If the valve has been disassembled the

cut-in adjustment screw should be fully

screwed in by turning it clockwise until

it bottoms out. Turn the cut-in screw

counterclockwise from the bottomed out

state one half turn. From here proceed by

adjusting screw #4 to desired pressure

and then screw #2. Gradually adjust both

screws, one at a time, until the proper set

points have been reached. Once the set

points are satisfactory, use screws #1 and

#3 to lock the adjustment screws in place.

NOTICE!

The lever at the end opposite the

inlet connection can be used to

manually switch between the open/

closed states.

4

3

2

1

MANUAL

LOAD

/

UNLOAD

LEVER

PILOT

LINE

OUT

AIR

IN

Quincy Compressor-DEFENDER™

11