Section II - Description

System Description

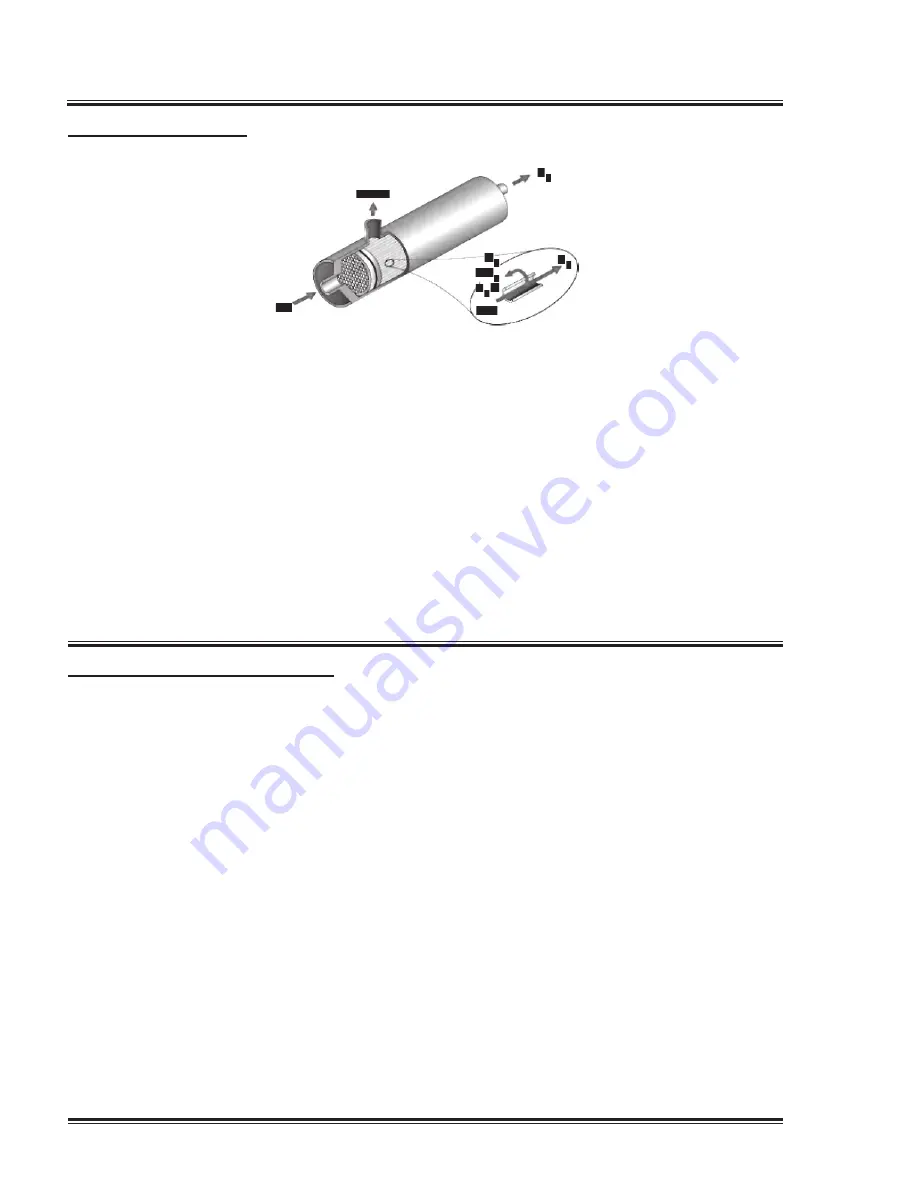

The DEFENDER™

Series utilizes a hollow

fi ber semi-permeable

membrane for the

separation of nitrogen

and other gases from a

compressed air stream.

The membranes divide

the air into two streams;

one is essentially nitrogen along with argon

and traces of other inert gasses. The other

stream is oxygen plus carbon dioxide,

hydrogen and other trace gases.

While fast gases such as oxygen, carbon

dioxide and water vapor quickly permeate

the membrane surface, most of the nitrogen

fl ows inside the membrane fi ber as a

separate product stream. Millions of fi bers,

about the size of a human hair, can be

packed into a single module. This provides

a very large membrane surface area that

effi ciently produces large quantities of

nitrogen.

This system is designed

to deliver nitrogen plus

other inert gases at

specifi ed concentration.

Because water vapor

is being permeated out

of the gas stream, the

resulting atmospheric

dew point is -85°F (-

65°C) or below.

The system is designed to operate with

feed air from a plant compressed air

system that has been dried to at least

+40°F (4°C) pressure dew point.

The membrane modules are protected from

hydrocarbons by a highly effi cient, six-step

fi ltration system. This system consists of a

combination of particulate, coalescing fi lters

and carbon adsorption. The result is air

purity with a heavy hydrocarbon carryover

at or below 2 parts per billion.

Nitrogen System Description

Inside the DEFENDER™ nitrogen

generator, the compressed air fi rst

comes into contact with the membrane

pre-fi ltration system. On Standard and

Premium Filtration Packages, this consists

of a coalescing fi lter (#1) followed by an

additional high effi ciency coalescing fi lter

(#2). On Standard Filtration Packages, the

fi nal pre-fi lter is a high effi ciency absorbing

fi lter (#3) which removes vapors and

aerosols.

On Premium Filtration Packages, the

second coalescing fi lter is followed by an

oversized carbon bed that eliminates any

vapor or aerosol that may have been left

and a fi nal dust fi lter (#4), installed after

the carbon bed, removes any charcoal

dust before the air reaches the membrane

bundles.

These fi lters are sized for low system

pressure drop (<2 PSI under maximum

conditions – 200 PSIG). Automatic

condensate drains are installed on each

fi lter to discharge oil and water. These

are joined into a common header and

connected to a single drain connection.

After the pre-fi ltration system, the purifi ed

air enters the separation membrane where

oxygen, water vapor, and trace gases

are removed from the air stream and

discharged to atmosphere via a vent on the

membrane module. The nitrogen product

fl ow and purity is controlled by a manually-

adjustable valve. This valve assures a near

constant fl ow, regardless of fl uctuating

downstream pressure. A non-return check

valve keeps nitrogen in the system from

venting back into the generator when unit is

stopped.

AIR

4

Quincy Compressor-DEFENDER™