Section IV - Installation

Installation Instructions

The Quincy DEFENDER™ nitrogen

generator is designed for ease of

installation. Since it is a packaged system,

a single-point air inlet, condensate drain,

and an outlet connection for nitrogen gas

(N2 out) need to made before the unit can

be placed into operation (see below for

connection sizes). The nitrogen generator

is mounted on a vertical tank or can be wall

mounted and piped to a receiver tank.

Location & Setting of Unit

The unit should be installed indoors on

a level surface capable of supporting the

static weight of the equipment (with 80 gal.

tank is approx. 305 lbs.). The tank should

be anchored to the floor. The unit should

be installed in a well-ventilated area where

the ambient temperature range will be

between 70° and 104°F (21°-40°C).

Inlet Air Quality

Compressed air should be supplied to

the unit with the air dried to a dew point

temperature lower than the expected

minimum ambient temperature. Typical dew

point from a properly sized refrigerated air

dryer is sufficient (+40°F / 4°C). No water

in liquid form should be present. Inlet

air pressure must be 200 psig or less.

An advanced system of oil and particle

removing filtration is included in the

nitrogen generator, so pre-filtration is not

required.

Condensate Drain Connections

A bulkhead connection is provided on the

bottom of the panel to connect to the floor

drain or other disposal methods to pipe

away oily condensate from the system.

Please note that it is normal to find oil in the

condensate when feed compressor source

is of the lubricated type. (Refer to Safety

- Environmental.) Do not install any valves

past the drain bulkhead.

Nitrogen Piping Connections

The final nitrogen connection is made into

a bulkhead connection on the top of the

panel. No other check valves are required

or recommended beyond this point.

Compressed Air Inlet Connection

An NPT connection is provided for the feed

air inlet (see below for connection sizes).

For systems without an Auto Start/Stop it

is recommended that an isolation valve be

installed at the inlet of the unit. This must

be a gate valve or other slow-opening

valve. On such units, opening the valve

too quickly can cause a rupture of the filter

elements due to rapid pressurization. Unit

failure as a result of an improper valve or

its use are not covered under the warranty.

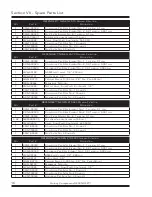

Connection Sizes

DEFENDER™ Model Feed Air Inlet Outlet Connection

N2GEN 25-70

¼” NPT

¼” NPT

N2GEN 270-520

½“ NPT

¼” NPT

N2GEN 870

½“ NPT

½“ NPT

N2GEN 1800

1“ NPT

½“ NPT

8

Quincy Compressor-DEFENDER™