Section I - General Information

NOTICE!

Every effort has been taken to ensure

complete and correct instructions

have been included in this manual,

however, possible product updates and

changes may have occurred since this

printing. Quincy Compressor reserves

the right to change specifications

without incurring any obligation for

equipment previously or subsequently

sold. Not responsible for typographical

errors.

Introduction

This manual describes the installation,

operating, and maintenance instructions for

the Quincy DEFENDER™ Series nitrogen

generator. Please read and be familiar with

this manual before attempting to operate

the unit. Although this unit is very simple to

operate, the user will be working with high-

pressure gas that must be handled with

caution.

DANGER!

Compressed gas, if handled improperly,

can result in serious or fatal injury.

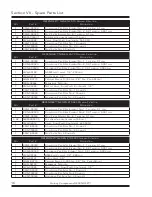

Spare Parts Ordering Information

Quincy Compressor maintains replacement

parts for all Quincy compressor products.

A repair parts list for the Quincy

DEFENDER™ can be found in the back

of this manual. Order parts from your

Authorized Quincy distributor. Use only

genuine Quincy replacement parts. Failure

to do so may void warranty.

Servicing Information

For questions not addressed in this manual

concerning the operation, maintenance or

repair of the DEFENDER™, please contact

your local Quincy Distributor.

2

Quincy Compressor-DEFENDER™