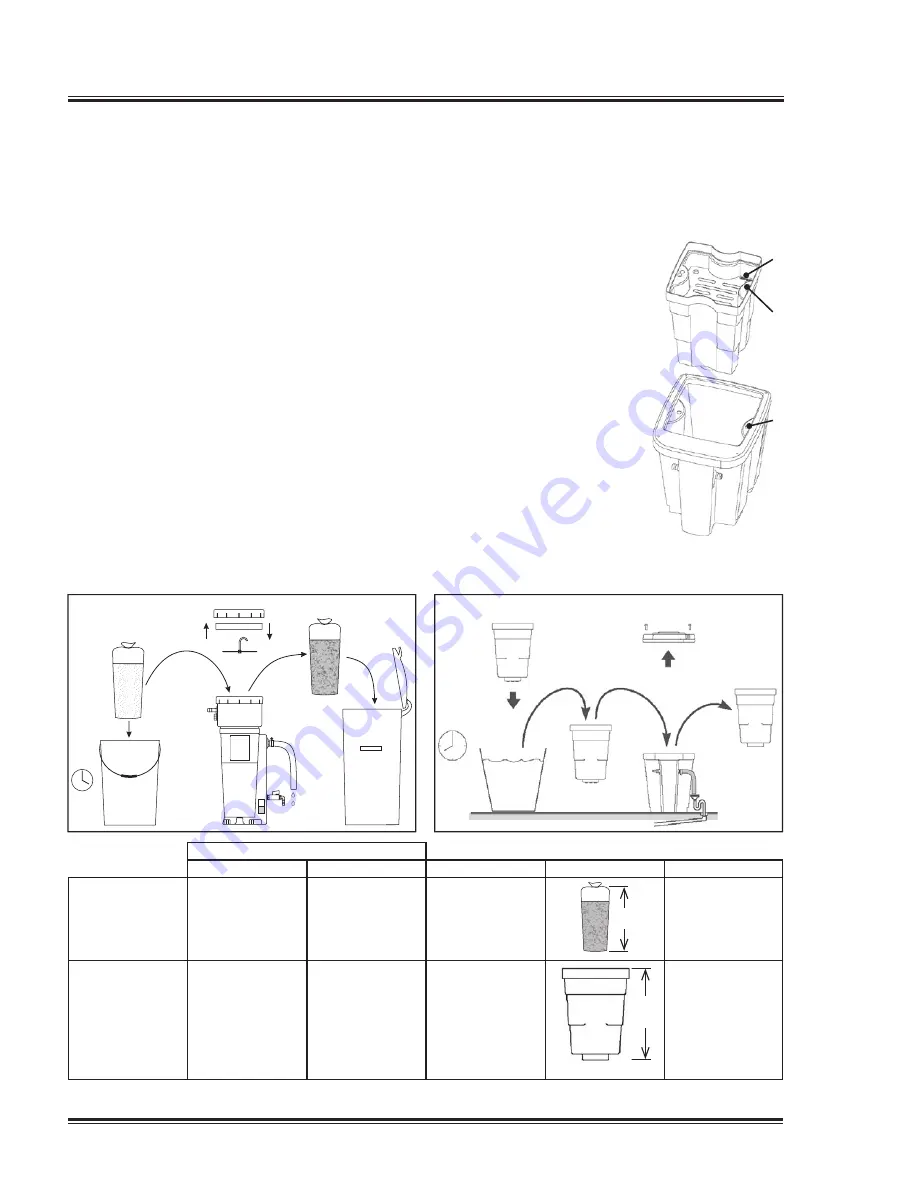

Maintenance

Cartridge Replacement Procedure

1. Place new Quincy cartridge set near the

unit. Keep the plastic bag of the new set

for wrapping up the old fi lters. Soak new

fi lter in tap water for 24 hours.

2. Shut off condensate inlet.

3. Open EWS lid.

4. Lift cartridge and allow

it to drain. Put fi lter into

the plastic bag and

close bag tightly.

5. Clean cartridge area.

6. Insert the new cartridge

slowly and ensure that

the guide pins (A)

fi t

into the container holes

(B).

7. Put back the lid.

8. Open condensate inlet.

9. Ensure correct disposal

of the fouled cartridge

in the plastic bag

provided.

F

ILTER

R

EPLACEMENT

K

IT

CONTAINS

:

P

REFILTER

A

DSORPTION

F

ILTER

W

EIGHT

D

IMENSIONS

K

IT

P

ART

N

UMBER

EWS 20

1

X

0.5

GAL

.

1

X

0.8

GAL

.

(

CONICAL

)

2.2

LBS

.

12"

2801190

EWS 100

1

X

3.2

GAL

.

1

X

2.1

GAL

.

(

CONICAL

)

19.8

LBS

.

19.7"

4007531

A

B

C

Cartridge Replacement

• It is recommended that an original Quincy

cartridge be kept in stock at all times.

• Use only Quincy cartridge to ensure

operational reliability. The original cartridges

are identified by their labelling (C) and test

seal.

• The correct functioning of the EWS

(wastewater quality, through-put capacity,

service life) cannot be guaranteed if any

other filter material is used.

• Soak new cartridge in tap water for 24

hours.

• Remove plastic bag before cartridge

installation.

EWS 20

1

5

6

3

9

4

2

8

24 h

H

2

O

7

EWS 100

1

24 h

2

8

3

4

9

5

6

7

12

Quincy Compressor-EWS Emulsion Separator