Installation proposal

Installation proposal

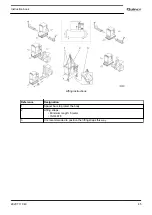

Ref.

Action

1

Main power switch for the compressor (three-phase).

Power supply cables need to be protected by suitable conduit.

2

Main power switch for the dryer (single-phase).

Power supply cables need to be protected by suitable conduit.

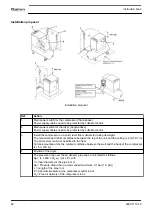

3

Install the compressor on a solid, level floor suitable for taking its weight.

The recommended minimum distance between the top of the unit and the ceiling is 2 m (78.7 in).

The air receiver must not be bolted to the floor.

For tank-mounted units, the minimum distance between the wall and the back of the compressor

is 1.5 m (59 in).

4

Position of the dryer.

The pressure drop over the air delivery pipe can be calculated as follows:

Δp = (L x 450 x Q

c

1.85

) / (d

5

x P), with

d = Inner diameter of the pipe in mm

Δp = Pressure drop in bar (recommended maximum: 0.1 bar (1.5 psi))

L = Length of the pipe in m

P = Absolute pressure at the compressor outlet in bar

Q

c

= Free air delivery of the compressor in l/s

Instruction book

46

2920 7113 40

Summary of Contents for QGS 10

Page 1: ...Quincy Oil injected rotary screw compressors QGS 10 QGS 15 QGS 20S Instruction book ...

Page 2: ......

Page 18: ...2 3 Oil system Oil system Oil system units with dryer Instruction book 16 2920 7113 40 ...

Page 23: ...Electric cubicle UL DOL Instruction book 2920 7113 40 21 ...

Page 51: ...208 230 460V 60Hz Instruction book 2920 7113 40 49 ...

Page 68: ...The new service interval is now set Instruction book 66 2920 7113 40 ...

Page 74: ...Line filters Instruction book 72 2920 7113 40 ...

Page 84: ...8 Problem solving Control panel Air outlet valve Instruction book 82 2920 7113 40 ...

Page 85: ...Oil filler plug Condensate drain valve on air receiver Instruction book 2920 7113 40 83 ...

Page 94: ......

Page 95: ......