Step

Action

5

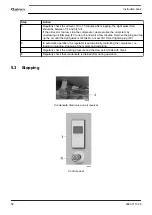

Regularly check the oil level. 10 to 15 minutes after stopping, the sight glass (SG)

should be between 1/4 and 3/4 full.

If the oil level is too low, stop the compressor, depressurise the oil system by

unscrewing oil filler plug (FC) one turn and wait a few minutes. Remove the plug and top

up the oil, until the sight glass is 3/4 full. Do not overfill. Fit and tighten plug (FC).

6

In automatic operation, the regulator is automatically controlling the compressor, i.e.

loading, unloading, stopping of the motors and restarting.

7

Regularly check the working pressure and the dew point (Units with dryer).

8

Regularly check that condensate is drained (Da) during operation.

5.3

Stopping

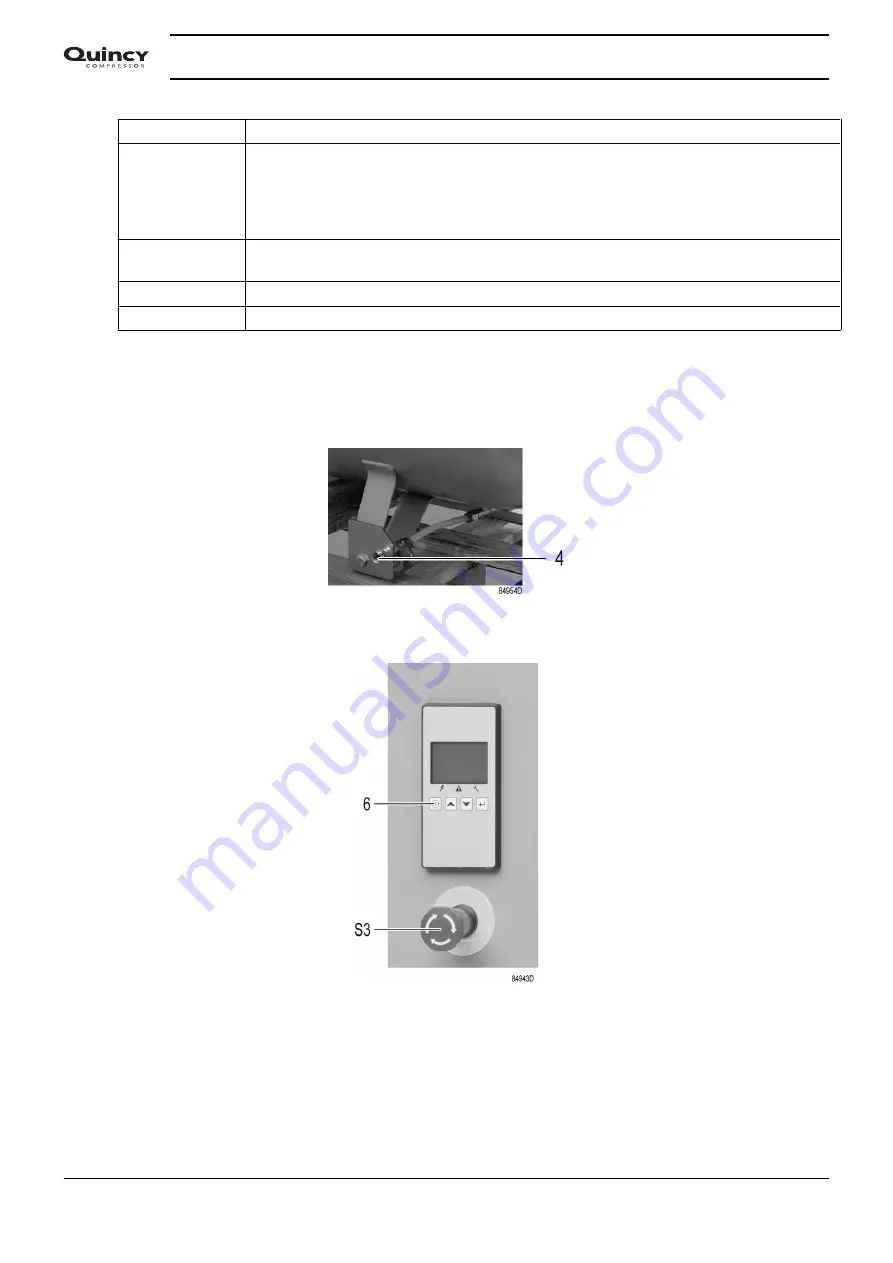

Condensate drain valve on air receiver

Control panel

Instruction book

58

2920 7113 40

Summary of Contents for QGS 10

Page 1: ...Quincy Oil injected rotary screw compressors QGS 10 QGS 15 QGS 20S Instruction book ...

Page 2: ......

Page 18: ...2 3 Oil system Oil system Oil system units with dryer Instruction book 16 2920 7113 40 ...

Page 23: ...Electric cubicle UL DOL Instruction book 2920 7113 40 21 ...

Page 51: ...208 230 460V 60Hz Instruction book 2920 7113 40 49 ...

Page 68: ...The new service interval is now set Instruction book 66 2920 7113 40 ...

Page 74: ...Line filters Instruction book 72 2920 7113 40 ...

Page 84: ...8 Problem solving Control panel Air outlet valve Instruction book 82 2920 7113 40 ...

Page 85: ...Oil filler plug Condensate drain valve on air receiver Instruction book 2920 7113 40 83 ...

Page 94: ......

Page 95: ......