3

Graphic controller

3.1

Controller

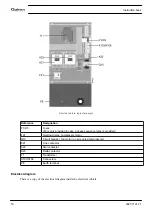

View of the AIRLOGIC² controller

Introduction

The electronic controller has following functions:

• Controlling the compressor

• Protecting the compressor

• Monitoring components subject to service

• Automatic restart after voltage failure

Automatic control of the compressor

The controller maintains the net pressure between programmable limits by automatically loading and

unloading the compressor (fixed speed compressors) or by adapting the motor speed (compressors with

frequency converter). A number of programmable settings, e.g. the unloading and loading pressures (for fixed

speed compressors), the setpoint (for compressors with frequency converter), the minimum stop time and the

maximum number of motor starts and several other parameters are taken into account.

The controller stops the compressor whenever possible to reduce the power consumption and restarts it

automatically when the net pressure decreases. If the expected unloading period is to short, the compressor

is kept running to prevent too short stand-still periods.

A number of time based automatic start/stop commands may be programmed. Take into

account that a start command will be executed (if programmed and activated), even after

manually stopping the compressor.

Protecting the compressor

Shut-down

Several sensors are provided on the compressor. If one of the measured signals exceeds the programmed

shutdown level, the compressor will be stopped.

Instruction book

2920 7101 21

17

Summary of Contents for QGS 40

Page 1: ...QGS 40 QGS 50 QGS 60 QGS 75 QGS 100 Instruction book Oil flooded rotary screw compressors...

Page 2: ......

Page 100: ......

Page 101: ......