6

Maintenance

6.1

Preventive maintenance schedule

Warning

Before carrying out any maintenance, repair work or adjustments, proceed as

follows:

•

Stop the compressor.

•

Press the emergency stop button.

•

Switch off the voltage.

•

Close the air outlet valve and open, if provided, the manual condensate drain valve.

•

Depressurise the compressor.

For detailed instructions, see section

The operator must apply all relevant

Warranty - Product Liability

Use only authorised parts. Any damage or malfunction caused by the use of unauthorised parts is not covered

by Warranty or Product Liability.

Service kits

For overhauling or carrying out preventive maintenance, service kits are available (see section

Service contracts

.QUINCY offers several types of service contracts, relieving you of all preventive maintenance work. Consult

your Customer Center.

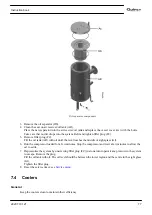

General

When servicing, replace all removed gaskets, O-rings and washers.

Intervals

The local Customer Center may overrule the maintenance schedule, especially the service intervals, depending

on the environmental and working conditions of the compressor.

The longer interval actions and checks must also include the shorter interval actions and checks.

Instruction book

2920 7101 21

71

Summary of Contents for QGS 40

Page 1: ...QGS 40 QGS 50 QGS 60 QGS 75 QGS 100 Instruction book Oil flooded rotary screw compressors...

Page 2: ......

Page 100: ......

Page 101: ......