7.2

Oil and oil filter change

Warning

The operator must apply all relevant

.

Always drain the compressor oil at all drain points. Used oil left in the compressor can

contaminate the oil system and can shorten the lifetime of the new oil.

Never mix lubricants of different brands or types as they may not be compatible and the

oil mix will have inferior properties. A label, indicating the type of oil filled ex-factory, is

stuck on the air receiver/oil tank.

Procedure

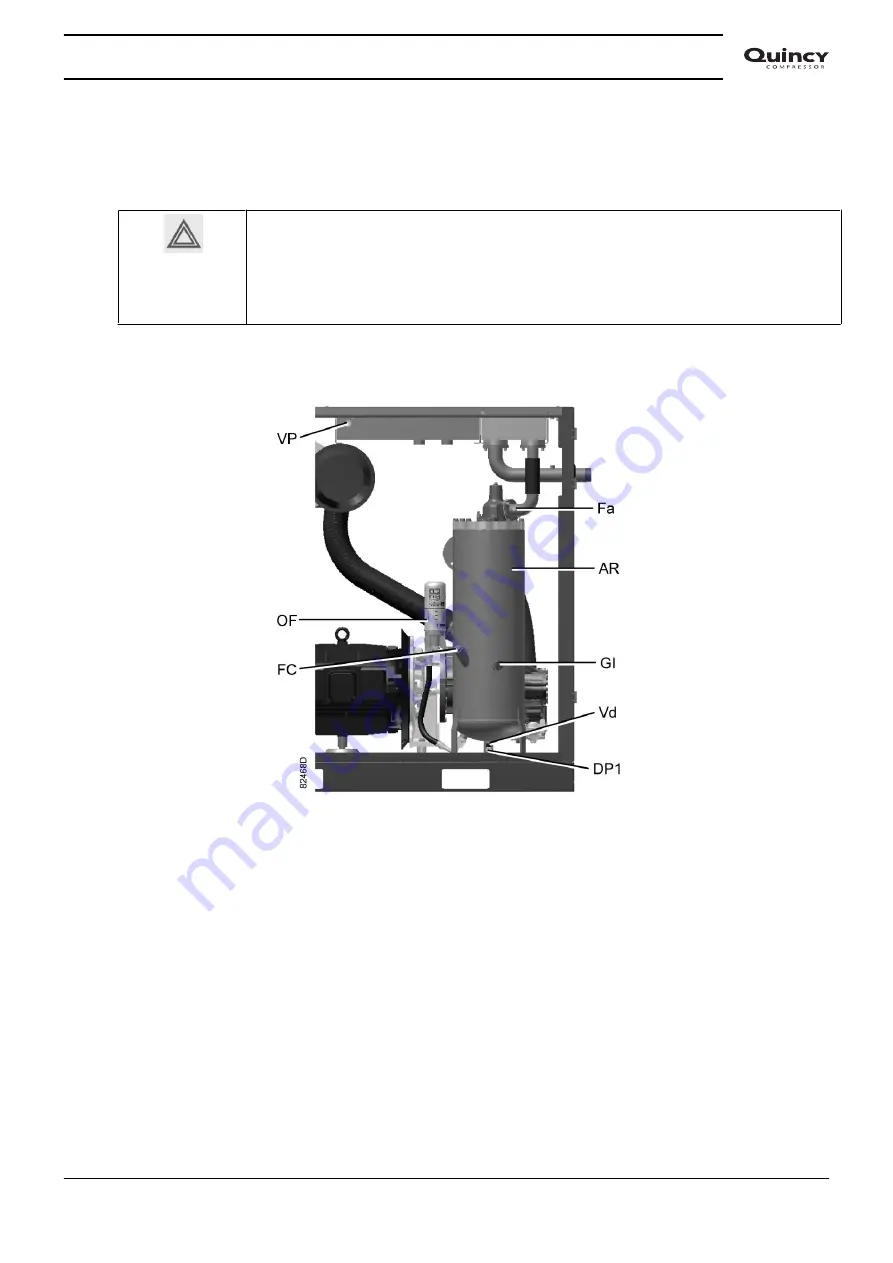

Oil system components

1. Run the compressor until warm. Stop the compressor. Close the air outlet valve and switch off the voltage.

Depressurise the compressor by opening manual drain valve(s) (if available). Wait a few minutes and

depressurise the air receiver/oil tank (AR) by unscrewing oil filler plug (FC) just one turn to permit any

pressure in the system to escape. Also depressurize the air pipe by unscrewing the air vent plug (Fa) with

one turn.

2. Loosen the vent plug (VP) of the oil cooler and wait for 5 minutes.

3. Remove oil drain plug (DP1). Drain the oil by opening valve (Vd). Close the valve and fit the plug after

draining.

Instruction book

2920 7101 21

75

Summary of Contents for QGS 40

Page 1: ...QGS 40 QGS 50 QGS 60 QGS 75 QGS 100 Instruction book Oil flooded rotary screw compressors...

Page 2: ......

Page 100: ......

Page 101: ......