Section VI - Maintenance

Quincy Compressor

81

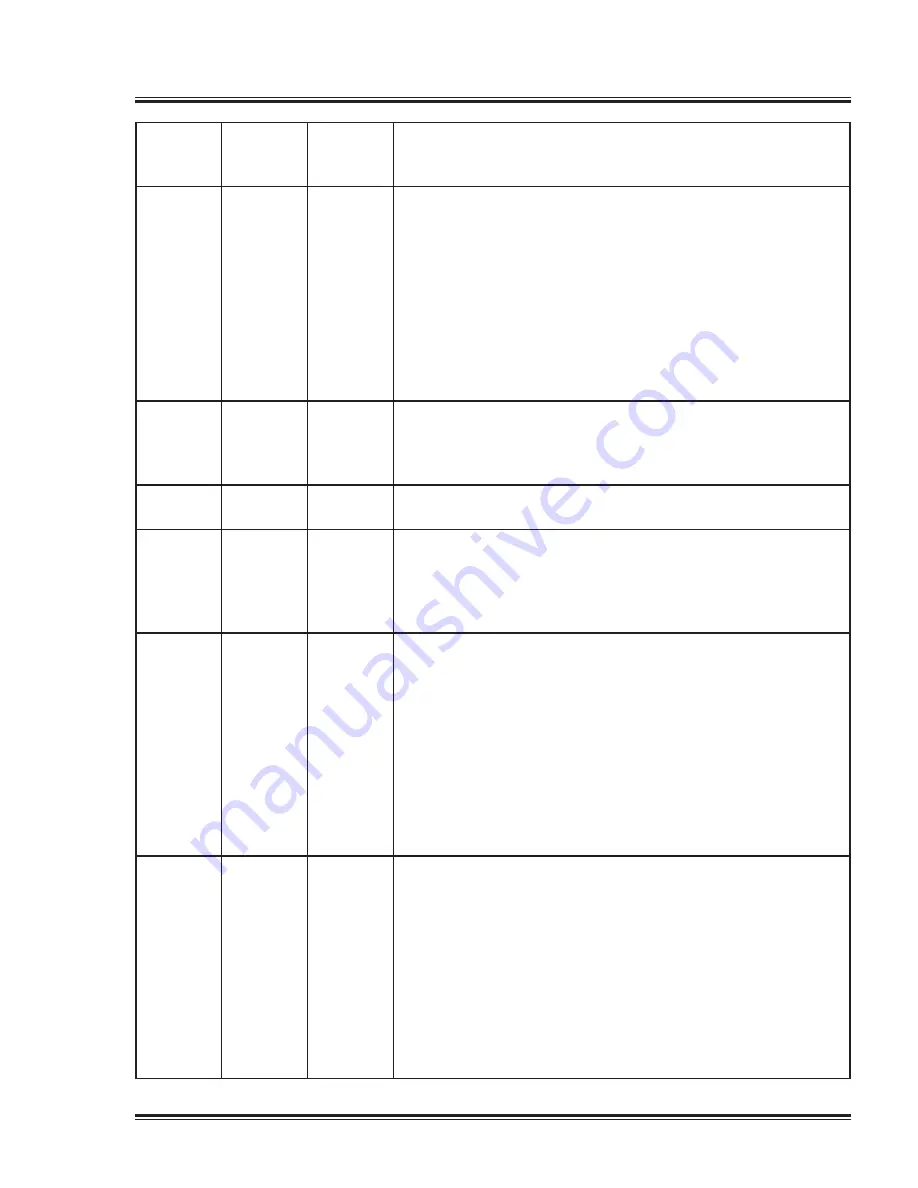

Period

(note 1)

Running

hours

(note 1)

Service

Plan

Operation

Every 6

months

1000

-

• Operate the safety valve.

• Clean the compressor.

• On compressors with integrated dryer:

• Brush or blow off the finned surface of the

condenser.

• Inspect and clean the electronic drain:

• Functioning of the drain can be checked by

pushing the TEST button of the drain.

• Cleaning of the drain filter can be done by

opening the manual drain valve during a few

seconds.

Yearly

2500

-

• Replace the air inlet filters.

• Test the safety valves.

• Have temperature protection and motor overload tested.

• Check tension and condition of the V-belts.

Every 2

years

5000

A

• Replace V-belt(s).

• Replace the check valves.

Every 2

years

5000

B

8 bar and 116 psi compressors:

• Clean fan (ref 124 on Flow diagram), fan duct and ele-

ment cooling fins (see note 2). See section Cleaning cooling

fins.

• Have orbiting scroll bearing greased (see note 3).

Every 2

years

5000

B

10 bar and 145 psi compressors:

• Replace the element outlet pipe and the plastic insert.

See section Outlet pipe replacement (3.7 kW elements

only).

• Clean fan (ref 124 on Flow diagram), fan duct and ele-

ment cooling fins (see note 2). See section Cleaning cooling

fins.

• Have orbiting scroll bearing and pin crank bearings

greased (see note 3).

• Replace tip seals and dust seal.

• Replace inlet seal.

Every 4

years

10000

B

8 bar and 116 psi compressors:

• Replace the element outlet pipe and the plastic insert.

See section Outlet pipe replacement (3.7 kW elements

only).

• Clean fan (ref 124 on Flow diagram), fan duct and ele-

ment cooling fins (see note 2). See section Cleaning cooling

fins.

• Have orbiting scroll bearing and pin crank bearings

greased (see note 3).

• Replace tip seals and dust seal.

• Replace inlet seal.