Section VIII - Problem solving

Quincy Compressor

89

NOTICE!

Before carrying out any maintenance or repair, perform following steps:

• Stop the compressor and switch off the voltage.

• Open and lock the isolating switch to prevent an accidental start.

• Isolate the compressor by closing the outlet valve.

• Depressurize the system by opening the drain valve(s).

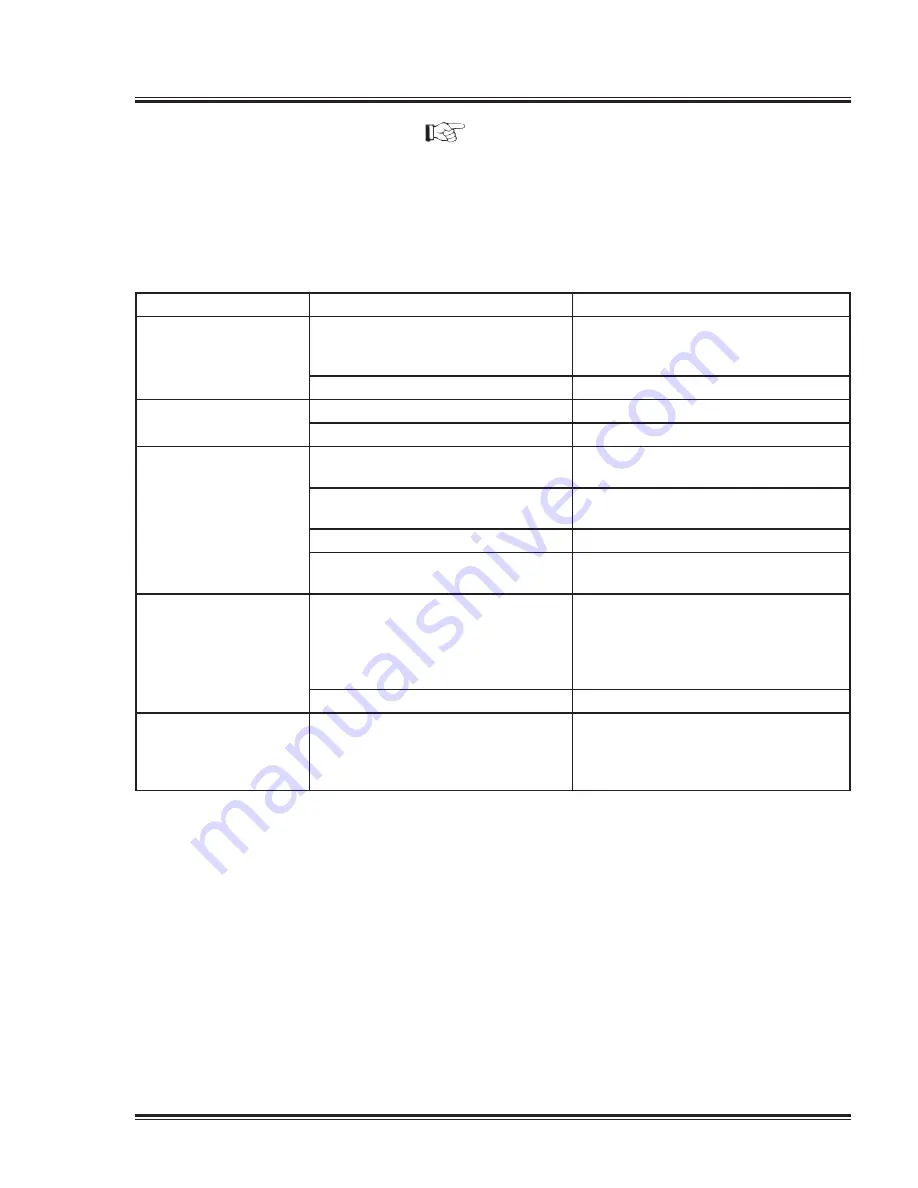

Compressor

Condition

Fault

Remedy

The compressor

does not start.

Pressure too high.

Compressor will start again

when the pressure drops to the

starting pressure.

Loose connection.

Check all electrical connections.

Safety valve blows.

Pressure too high

Check settings and correct.

Safety valve opens too soon.

Replace valve.

Compressor

capacity or pressure

below normal.

Air consumption exceeds

capacity of compressor.

Check equipment connected.

Choked air inlet filter.

Remove and check filter. Replace

if necessary.

Safety valve leaking.

Replace valve.

Compressor element out of

order.

Consult your supplier.

Compressor

module overheating

or compressor

shutdown on high

air temperature.

Insufficient compressor

cooling.

Improve ventilation of

compressor room. Clean

compressor element fins

and fan, see Cleaning the

compressor element.

Cooling fan out of order.

Check and correct.

Condensate trap

continuously

discharging air an

water

Automatic drain out of order

Have the drain checked. Replace

as necessary

Refrigerant dryer

For compressors with a built-in refrigerant dryer also: