July 2004

11

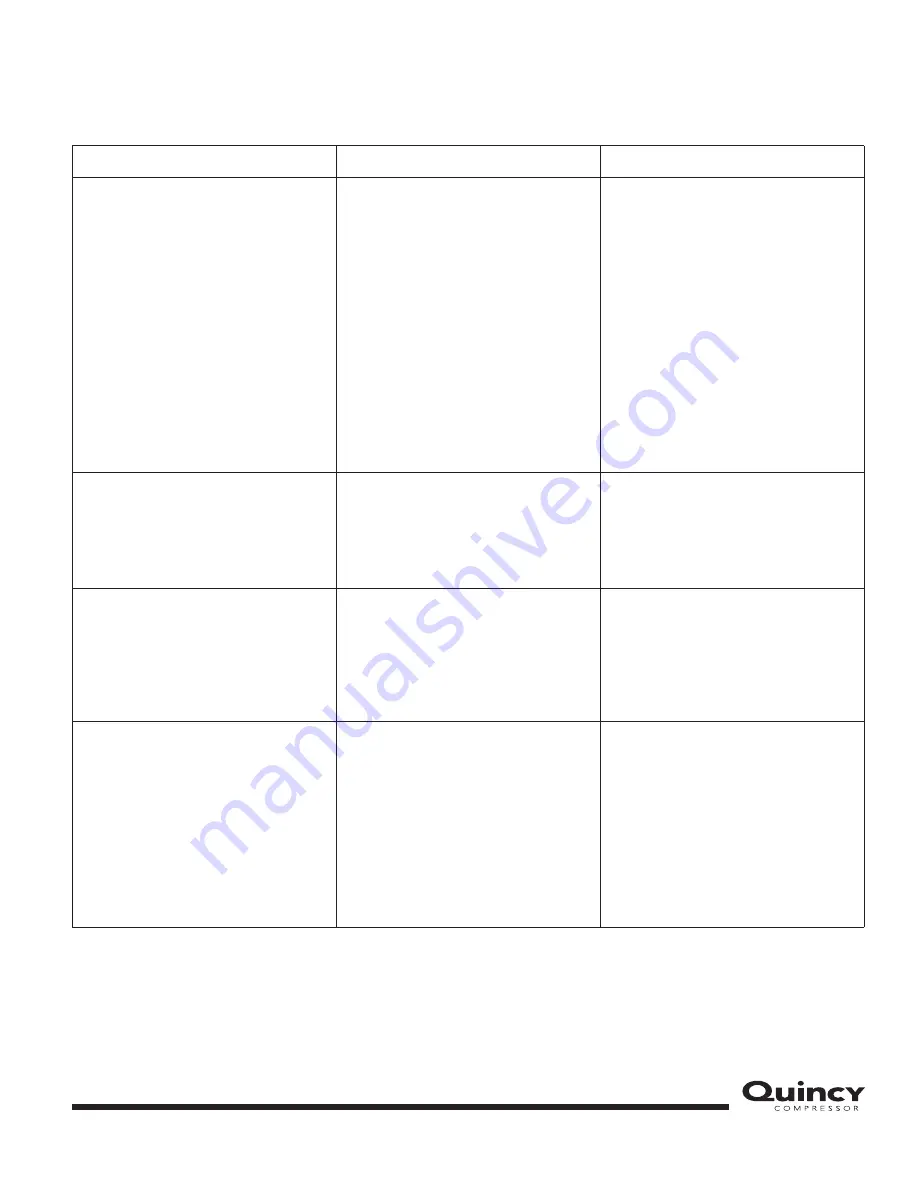

TROUBLESHOOTING

Table 1 — Troubleshooting Guide

Symptoms

Cause

Remedy

A. Moisture downstream.

1. Refrigeration compressor not

running.

2. Suction pressure reads above

blue/green zone.

3. Moisture separator auto drain

malfunction.

a. Check electric power supply.

b. If red light is on, call for factory

service.

a. Clean the air cooled condenser

(see Page 8).

b. Adjust hot gas bypass valve (see

Page 9).

c. Check for defective fan motor and

replace.

a. Check the auto drain operation

(see Page 8).

b. Check for clogged drain line from

auto drain outlet to floor drain.

c. Check the electronic timer for

loose wires or evidence of burn

out.

B. Oil downstream.

1. Oil filter malfunction.

2. Filter element dirty.

a. Check the drain operation.

b. Clean the drain if stuck or

clogged.

c. Check the drain manual valve for

clogging.

a. Replace element (see Page 8).

C. Low air pressure downstream.

1. Suction pressure below blue/

green zone. This causes freeze-up

in the air systems.

a. Adjust hot gas bypass valve (see

Page 9).

b. Low on refrigerant. Call for

service.

c. To confirm freeze-up, shut off the

unit for 15 minutes. Air pressure

should come back to line pressure.

D. Continuous air flow through the

moisture drain line.

1. Foreign materials lodged on the

valve seat.

2. Short-circuited timer board.

3. Short-circuited PUSH-TO-TEST

switch.

4. Defective solenoid valve.

a. Press the PUSH-TO-TEST switch

several times.

b. Disconnect the drain lines to the

solenoid valve and blow

compressed air from outlet while

pressing the PUSH-TO-TEST

switch.

a. Replace.

a. Replace.

a. Replace.

Summary of Contents for QPHT 20

Page 1: ...HIGH TEMPERATURE REFRIGERATED DRYER OPERATOR S MANUAL QPHT 20...

Page 15: ......

Page 16: ......

Page 17: ......

Page 18: ......