QR-25 Series

Quincy Compressor

52201-107, December 2012

20

3501 Wismann Lane, Quincy IL - 62305-3116

SECTION 4

START-UP & OPERATION

Pre-starting Checklist

Never assume a compressor is safe to work on just because it is not

operating. It could restart at any time. Follow all safety precau-

tions outlined in SECTION 5,

Stopping For Maintenance.

Failure to perform the pre-starting checklist may result in me-

chanical failure, property damage, serious injury or even death.

Steps 1 through 12 should be performed prior to connecting the

unit to a power source. If any condition of the checklist is not satisfied,

make the necessary adjustments or corrections before starting the compressor.

Step 1)

Remove all installation tools from the compressor and check for

installation debris.

Step 2)

Check lubricant level in crankcase. (Refer to SECTION 5,

Lubrication

for quantity and types of lubri cant to be used.)

Step 3)

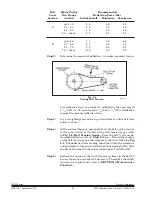

Check motor pulley and compressor sheaves for alignment and

tightness on shaft. (Refer to SECTION 5,

Pulley / Sheave Align-

ment & Belt Tension.

)

Step 4)

Manually rotate the compressor sheave several rotations to be

sure there are no mechanical interferences.

Step 5)

Check inlet piping installation (Refer to SECTION 3,

Induction

System.

)

Step 6)

Check belt tension. (Refer to SECTION 5,

Pulley / Sheave

Alignment & Belt Tension.

)

Step 7)

Check all pressure connections for tightness.

Step 8)

Make sure all pressure relief valves are correctly in stalled. (Refer

to SECTION 3,

System Components.

)

Step 9)

Be sure all guards are in place and securely mounted. (Refer to

SECTION 3,

System Components.

)

Step 10) Check fuses, circuit breakers, and overload relays for proper size.

(Refer to SECTION 3,

Electrical Supply Requirements.

)

Step 11) Open all manual shutoff valves at and beyond the compres sor

discharge.

Step 12) After all the above conditions have been satisfied, the unit can be

connected to the proper power source.

WARNING !

WARNING !

Summary of Contents for QR-25 210

Page 42: ......