QR-25 Series

Quincy Compressor

52201-107, December 2012

22

3501 Wismann Lane, Quincy IL - 62305-3116

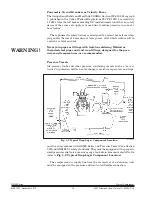

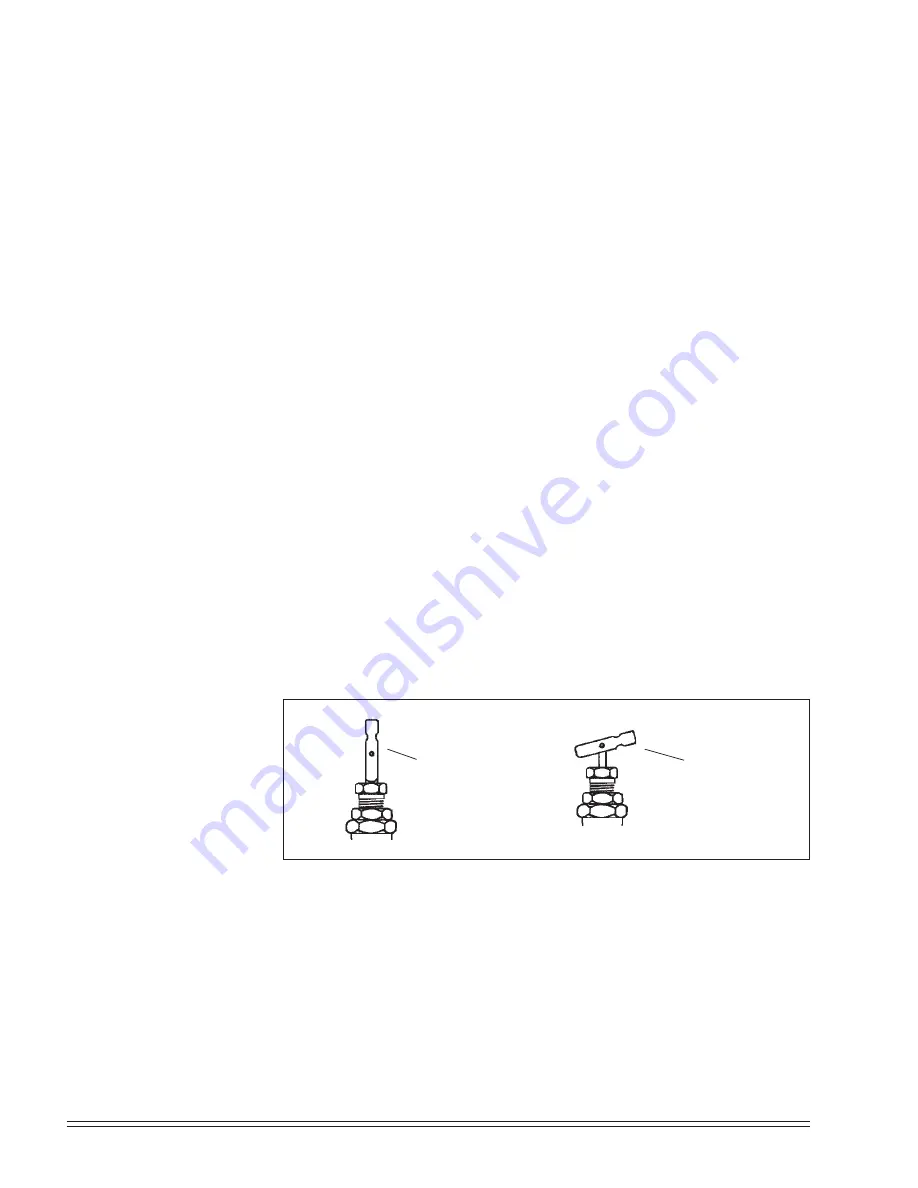

“MANUAL

UNLOAD”

position

“RUN”

position

Fig. 4-2

Continuous Run Pilot Valve

A new or rebuilt reciprocating compressor should be run for a total of 100

hours at full discharge operating pressure to breakin the new piston rings.

Until the rings are seated, the compressor will discharge higher than normal

amounts of lubricant. In light of this fact, the lubricant level should be checked

more frequently during the 100 hour breakin period.

Daily Starting Checklist

Do not proceed until the

Pre-starting Checklist

and

Initial Starting &

Operating

subsections have been read and are thor oughly understood.

Step 1)

Check the lubricant level in the crankcase.

Step 2)

Check all hoses and fittings for weak or worn conditions and re

place if necessary.

Step 3)

Drain liquid from the air receiver (refer to Section 3, Manually

Draining An Air Tank) and moisture trap (if so equipped).

Step 4)

Jog the starter button and check compressor rotation.

Note: Con-

tinuous Run Units - Prior to starting a continuous run unit, flip

the toggle lever on the pilot valve stem to the “MANUAL UNLOAD”

position (see below). Now the compressor can be started unloaded.

Once the compressor is running at full speed, flip the toggle back

to the “RUN” position.

Step 5)

Start compressor per factory instructions. (Refer to SECTION 4,

Pre-Starting Checklist and Initial Starting & Operating.

)

Step 6)

Check system pressure.

Step 7)

Check cooling fan.

Step 8)

Check all pressure relief valves for proper operation.

Step 9)

Check control system for proper operation.

Step 10) Check the lubricant level in the crankcase several minutes after

the compressor has run. (Discoloration or a higher lubricant level

reading may indicate the presence of condensed liquids.) If lubri

cant is contaminated, drain and replace.

Summary of Contents for QR-25 210

Page 42: ......