Section III - Installation

Quincy Compressor

®

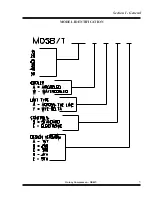

- QSB/T

™

15

Electrical

Before installation, the electrical supply should be

checked for adequate wire size and capacity. During

installation, a suitable fused disconnect switch or circuit

breaker should be provided. Any unreasonable voltage

unbalance (5%) between the legs must be eliminated and

any low voltage corrected to prevent excessive current

draw. The installation, electric motor, wiring and all

electrical controls must be in accordance with National

Electric Code, and all state and local codes. A qualified

electrician should perform all electrical work.

Air

compressors must be grounded in accordance with

applicable codes.

See control panel for the proper wiring

diagram.

Quincy would like to emphasize the importance of

providing adequate grounding for air compressors. The

common practice of grounding units to building structural

steel may not actually provide adequate grounding

protection, as paint and corrosion buildup may exist.

CAUTION!

NEMA electrical enclosures and components must

be appropriate to the area in which they are

installed.

Pneumatic Circuit Breakers or Velocity Fuses

The Occupational Safety and Health Act, Section

1926.303 Paragraph 7 published in Code of Federal

Regulations 29 CFR 1920.1 (revised 07/01/1982), states

“all hoses exceeding 1/2” inside diameter shall have a

safety device at the source of supply or branch line to

reduce pressure in case of a hose failure.” These

pneumatic safety devices are designed to prevent hoses

from whipping, which could result in a serious or fatal

accident.

Guards

All mechanical action or motion is hazardous in varying

degrees and needs to be guarded. Guarding shall comply

with OSHA Safety and Health Standards 29 CFR

1910.219 in OSHA manual 2206 (revised 11/07/1978)

and any state or local codes.

WARNING!

Cabinet panels and drive guards must be fastened

in place before starting the machine and never

removed before lock out/tag out of the main power

supply.

Manual Vent and Shutoff Valve

Install a manual valve to vent the compressor and the

compressor discharge line to atmosphere. If the air receiver tank

services a single compressor, the manual valve can be installed

in the receiver. When a manual shutoff valve (block valve) is

used, a manual valve should be installed upstream from the

valve, and a pressure relief valve installed upstream from the

manual vent valve. These valves are to be designed and

installed to permit maintenance to be performed in a safe

manner. Never substitute a check valve for a manual shutoff

valve (block valve) if the purpose is to isolate the compressor

from a system for servicing.

WARNING!

Relieve compressor and system air pressure by

opening the appropriate manual relief valve prior

to servicing. Failure to relieve all system pressure

could result in death or serious injury and

property damage.

Summary of Contents for QSB Series

Page 2: ......

Page 9: ...Section I General Quincy Compressor QSB T 5 MODEL IDENTIFICATION...

Page 21: ...Quincy Compressor QSB T 17 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 27: ...Quincy Compressor QSB T 23 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 71: ...Quincy Compressor QSB T 67 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 72: ...Appendix A Dimensional Drawings 68 Quincy Compressor QSB T QSB 15 50 HP air cooled...

Page 73: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 69 QSB 15 50 HP water cooled...