Section II - Description

Quincy Compressor

®

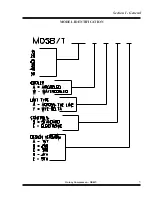

- QSB/T

™

7

Air Flow

When the compressor is operating, a partial vacuum is

produced at the compressor inlet. Air entering via the air

filter flows through the inlet valve into the rotor housing

where it is compressed, then discharged into the air/fluid

reservoir. Compressed air passes through the complete

system, then through a minimum pressure check valve to

the service connection.

Cooling System

Fluid Coolers

Fluid coolers may use either air or water as a cooling

medium. The following descriptions point out the major

differences between the two types of coolers.

Air-cooled Fluid Coolers

The air-cooled fluid cooler and aftercooler are finned

aluminum tube, one piece design. Ambient air is forced

through the fins by a motor driven fan, cooling the fluid

and air in the tubes. To maintain proper compressor

operation, the ambient air temperature should not exceed

the temperatures listed in Appendix B - Technical Data.

The cooler fins must be kept clean at all times. Fluid

leaving the receiver passes through a thermal mixing

valve before traveling on to the cooler. The purpose of

the thermal valve is to maintain a minimum fluid

discharge temperature at the compressor of approximately

180°F.

Water-cooled Fluid Coolers

Water-cooled fluid coolers are of the shell and tube

design. Fluid passes through the shell transferring its heat

to the water flowing through the tubes. Fluid leaving the

cooler does not pass through a thermal mixing valve as in

an air-cooled unit, but goes directly to

t

he fluid filter and

the compressor. Fluid discharge temperature at the

compressor is maintained by a water temperature

regulating valve located in the discharge water line. The

water temperature regulating valve uses a probe to sense

fluid temperature and opens and closes, governing water

flow through the cooler.

Aftercoolers

Aftercoolers reduce the amount of water in the discharge

air. They are used to lower the temperature of the

discharge air thereby condensing water vapor from the

compressed air. This allows most of the contained water

to be trapped and expelled from the unit, reducing water

related problems downstream.

Air-cooled aftercoolers are part of the air-cooled fluid

cooler. Cooling air from the fan is blown through the

aftercooler and the fluid cooler.

Water-cooled aftercoolers are placed in series with the

fluid cooler. Incoming water is first directed through the

aftercooler and then on to the fluid cooler.

Moisture Separator

A combination moisture separator and water trap is

provided for collecting and expelling water to the

customer’s drain.

Summary of Contents for QSB Series

Page 2: ......

Page 9: ...Section I General Quincy Compressor QSB T 5 MODEL IDENTIFICATION...

Page 21: ...Quincy Compressor QSB T 17 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 27: ...Quincy Compressor QSB T 23 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 71: ...Quincy Compressor QSB T 67 THIS PAGE INTENTIONALLY LEFT BLANK...

Page 72: ...Appendix A Dimensional Drawings 68 Quincy Compressor QSB T QSB 15 50 HP air cooled...

Page 73: ...Appendix A Dimensional Drawings Quincy Compressor QSB T 69 QSB 15 50 HP water cooled...