Section VIII - Service Adjustments

Quincy Compressor-QSI

®

109

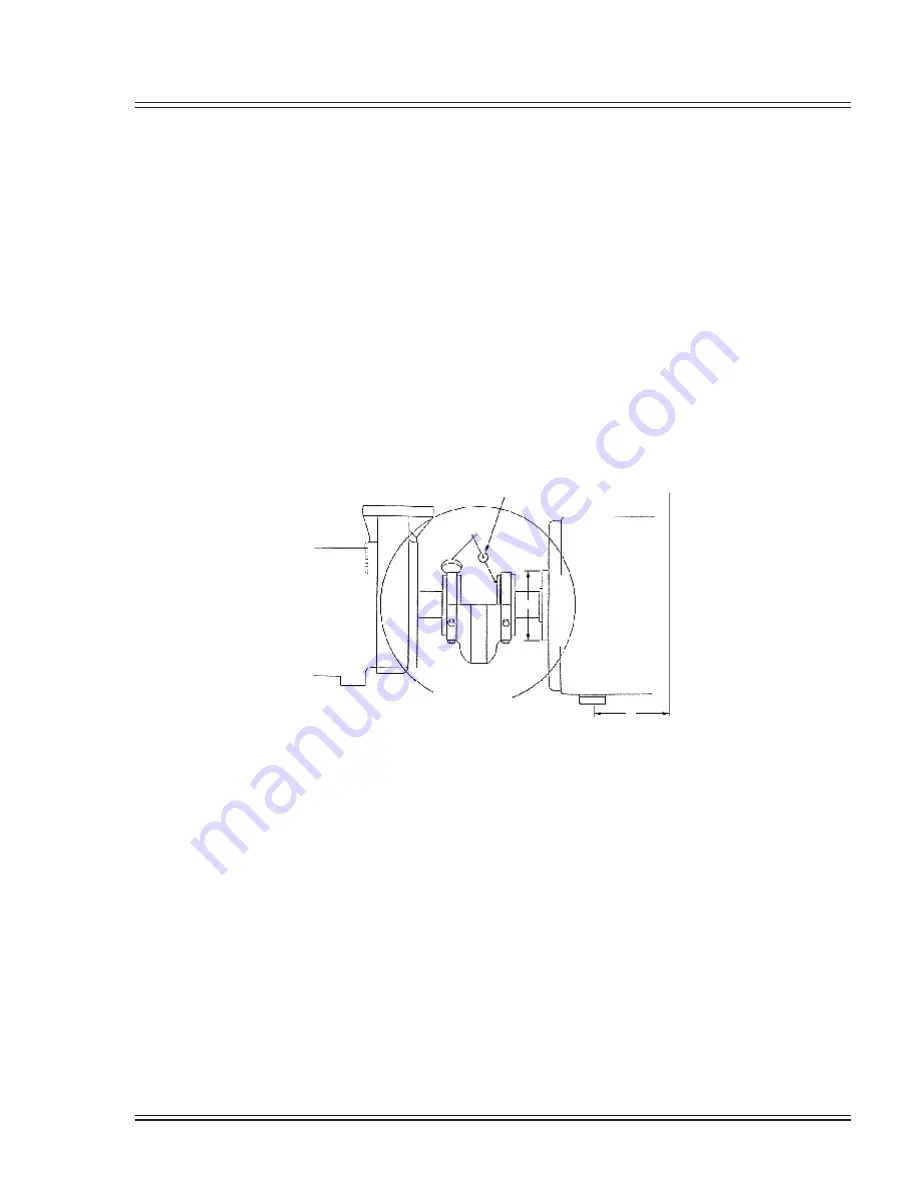

Correcting Angular Misalignment-Side View

1) With the indicator point on the face of the motor

half, zero the indicator.

2) Rotate the entire assembly 180° or one-half (1/2)

turn. Note the indicator reading. This reading is re

-

ferred to as “C” in the formula and example shown.

3) Measure the distance from center to center between

the motor feet. This will be referred to as “A”.

4) Measure the O.D. of the coupling. This will be

referred to as “B”.

5) Divide measurement “A” by measurement “B”.

6) Multiply the result from step 5 by the indicator

reading “C” to determine the amount of shim to be

placed under either the front feet or the rear feet of

the motor to correct misalignment.

Example (refer to Figure 8-1):

A = 5”, B = 4”, C = +0.028

Because C is a positive reading, the distance between the

coupling halves is greater at the top.

5/4 x 0.028 = 0.035 required shims

Angular Misalignment Viewed From the Top

1) Mount the dial indicator on the compressor coupling

AIREND

MOTOR

A = DISTANCE BETWEEN FEET

B = COUPLING DIAMETER

C = INDICATOR READING

C

A

B

A/B x C = REQUIRED SHIMS

Figure 8-1. Angular Misalignment-Side View

Summary of Contents for QSI Series

Page 2: ......

Page 7: ...Section I General Quincy Compressor QSI 5 MODEL IDENTIFICATION...

Page 62: ...Section IV Operating Procedures 60 Quincy Compressor QSI 1 Week Timer 2 Remaining Running Time...

Page 79: ...Section IV Operating Procedures Quincy Compressor QSI 77...