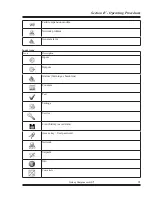

Section II - Description

Quincy Compressor-QSI

®

11

Indicators

Main Power on Light

Indicates when power from the main disconnect switch

has been turned on and there is live power at the com-

pressor starter and control panel. This light will remain

on as long as there is power to the unit, regardless of the

position of the selector switch.

CAUTION!

Always check power supply disconnect. The

Power-on light may be inoperable.

High Discharge Air Temperature Light

Indicates when the unit has sensed an unusually high

discharge temperature.

Fluid Filter Change Light

Indicates excessive pressure differential across the fluid

filter. It is used to determine fluid filter change intervals.

Air/Fluid Separator Element Differential Light

This indicates excessive pressure differential across the

air/fluid separator element. It is used to determine separa

-

tor element change intervals.

Air Intake Filter Service Light

This indicator signals when the filter element needs to be

cleaned or replaced.

Gauges

Hourmeter

This gauge indicates actual hours of operation.

Air Pressure Gauge

This gauge indicates air pressure available for distribution

to the service line.

CAUTION!

Gauge may not register when the unit is unloaded

or off. Make certain all air pressure is relieved

prior to servicing.

Air Outlet Temperature Gauge

This gauge indicates the temperature of the air/fluid mix

-

ture as it discharges from the compressor. The normal

reading is 170-190°F.

Percent Capacity Gauge

This gauge is graduated in percent of the total capacity of

the unit. Readings taken from this gauge give an indica

-

tion of the amount of air being used.

Summary of Contents for QSI Series

Page 2: ......

Page 7: ...Section I General Quincy Compressor QSI 5 MODEL IDENTIFICATION...

Page 62: ...Section IV Operating Procedures 60 Quincy Compressor QSI 1 Week Timer 2 Remaining Running Time...

Page 79: ...Section IV Operating Procedures Quincy Compressor QSI 77...