Section IV - Operating Procedures

34

Quincy Compressor-QSI

®

Overview

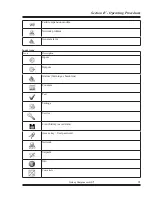

Text on figures

(1)

Overview

(2)

Running Hours (blue)

(3)

Real Time hours (black)

(4)

Reset

Example for service level (A):

The figures at the left are the programmed service intervals. For Service interval A, the programmed number of

running hours is 4000 hours (upper row, blue) and the programmed number of real time hours is 8760 hours, which

corresponds to one year (second row, black). This means that the controller will launch a service warning when either

4000 running hours or 8760 real hours are reached, whichever comes first. Note that the real time hours counter keeps

counting, also when the controller is not powered.

The figures within the bars are the number of hours to go till the next service intervention. In the example above, the

compressor has been running for an hour and so it has 3999 more running hours or 8759 more real time hours to go

before the next Service intervention.

Service plans

A number of service operations are grouped (called Level A, Level B, etc...). Each level stands for a number of service

actions to be carried out at the time intervals programmed in the Q-Control.

When a service plan interval is reached, a message will appear on the screen.

After carrying out the service actions related to the indicated levels, the timers must be reset.

From the Service menu above, select Service plan (3) and press Enter. Following screen appears:

Summary of Contents for QSI Series

Page 2: ......

Page 7: ...Section I General Quincy Compressor QSI 5 MODEL IDENTIFICATION...

Page 62: ...Section IV Operating Procedures 60 Quincy Compressor QSI 1 Week Timer 2 Remaining Running Time...

Page 79: ...Section IV Operating Procedures Quincy Compressor QSI 77...