Page 12

Biasi SG Pro Series

4.2 Reversing the Boiler Door Hinge

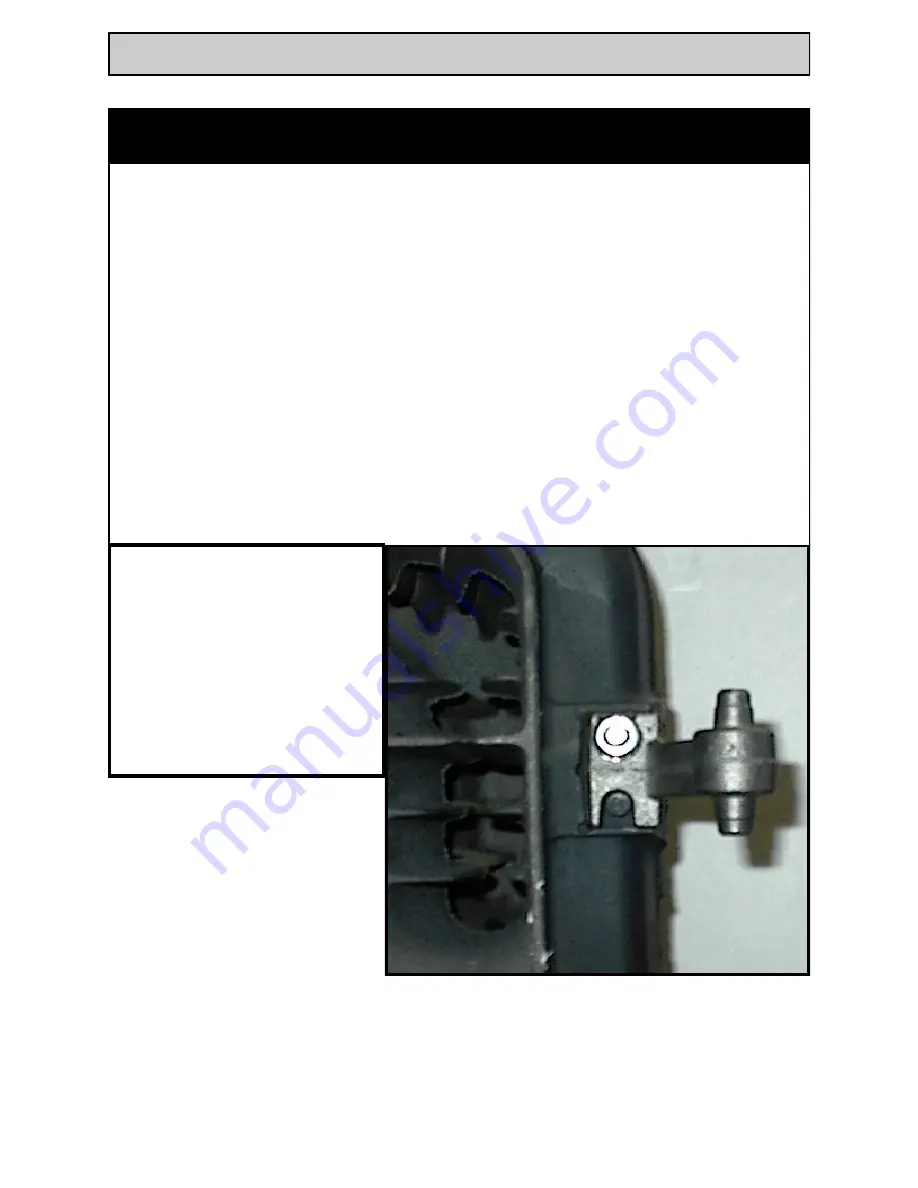

1. Remove the boiler door by unscrewing the two nuts holding the door onto the boiler

2. Remove the hinge components from the door and boiler body.

3. Take the boiler hinge elements (it has the pins on the ends) and place them on the upper

and lower studs of the side of the boiler that you want the door to swing towards. Install

them such that the stud comes through the upper “U”-section and the pin on the boiler block

is under the lower “U” section of the hinge. (see Figure 4.1 below) Tighten each with a

washer and a nut.

4. Next place the door catch under the top post of the side opposite that on which the hinges

are mounted. This is mounted in a similar manner to the hinges. Tighten with a washer

and a nut.

5. Place the bolts with a washer on each through the back of the ears on the door in the upper

and lower holes on the same side as the hinges are mounted on.

6. Place the upper hinge element onto the bolt and tighten with a washer and a nut.

7. Place the doors hinges onto the pins of the hinge on the boiler.

8. The installation of the hinge is complete. Now, close the door and put the nuts and washers

back onto the door to keep shut

SG Hinge Kit Components:

5—Nuts

7—Washers

2—Bolts

2—Lower hinge elements

2—Upper hinge elements

1—Door Catch

Summary of Contents for SG-3

Page 2: ...Page 2 Biasi SG Pro Series...

Page 33: ...Biasi SG Pro Series Page 33 Notes...

Page 34: ...Page 34 Biasi SG Pro Series Notes...