Page 20

Biasi SG Pro Series

Good, reliable operation with a minimum of service, starts with attention to the small details:

1. Setting electrodes "by the book" using the manufacturer's gauges.

2. Checking gas pressure to the burner and out of the gas valve.

3. Checking draft at the breeching to insure it is adequate to overcome flue

gas resistance.

4. Setting the air band properly with well maintained instruments. A good

target is 8.5% to 9.5% of (CO

2

) for Natural Gas or 10% to 11% of (CO

2

) for

Propane.

7. Verify a CO level is less than 200 ppm

This page is only for boilers using a gas burner. If an oil burner is being used, please refer to

page 12 for the proper setup of the burner.

To determine how much gas is coming into the burner,

or to set the gas meter correctly, the following formula

can be used.

The chart to the right can be used to determine the

flow rate depending upon the time per revolution and

the size of the gas meter dial.

Ft

3

/hr = [3600/(sec. Per rev.)/*(Size of gas meter)

Size of Gas Meter Dial

(Cubic Foot)

Seconds per

Revolution

0.5

1

2

20

90

180

360

25

72

144

288

30

60

120

240

35

51

103

206

40

45

90

180

45

40

80

160

50

36

72

144

55

33

65

131

60

30

60

120

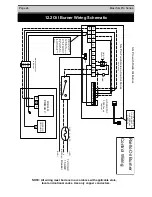

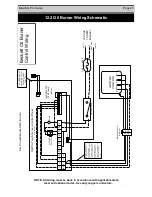

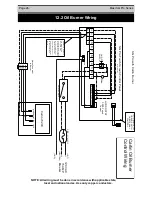

8.2 Gas Burner Setup

Riello

Natural Gas

Propane

Boiler

Model

Burner Model

Input

(MBH)

Man. Pres.

(W.C.)

Head

Setting

Air

Gate

Orifice

Man. Pres.

(W.C.)

Head

Setting

Air

Gate

Orifice

SG-3

R200

140

3.5”

2.0

2.25

B5

3.5”

2.0

2.25

B15

SG-4

R200

182

3.5”

3.0

2.75

B6

3.5”

3.0

2.5

B16

SG-5

R400

224

3.5”

1.0

2.0

C3

3.5”

1.0

1.5

C13

Summary of Contents for SG-3

Page 2: ...Page 2 Biasi SG Pro Series...

Page 33: ...Biasi SG Pro Series Page 33 Notes...

Page 34: ...Page 34 Biasi SG Pro Series Notes...